Industrial operations maintain optimal performance and safety through various types of ICSS (Integrated Control and Safety Systems). These systems combine control and safety functions, enabling real-time monitoring and regulation of industrial processes. ICSS integrates hardware and software components to enhance operational efficiency and prioritize safety across industries.

SCADA systems, a key component of ICSS, facilitate centralized monitoring by allowing operators to oversee and control industrial processes from a centralized location.

ICSS technologies include smart sensors, sensor fusion, sensor networks, and IoT sensors. These components collect, analyze, and transmit data for informed decision-making. With ICSS, industrial facilities can optimize production, detect hazards, and mitigate risks, creating a safer working environment.

ICSS implementation has significantly improved process optimization, operational stability, and regulatory compliance. Industries like manufacturing, energy management, and water treatment rely on Electronic Applications of Industrial Control Systems. Transportation and healthcare sectors also use ICSS to streamline operations and ensure workforce safety.

By leveraging types of ICSS, organizations achieve higher efficiency, reliability, and safety levels. This technology’s impact on industrial landscapes is undeniable, making it crucial for modern operations.

Key Takeaways

ICSS integrates control and safety functions to optimize industrial operations and ensure personnel and asset safety.

Smart sensors, sensor fusion, sensor networks, and IoT sensors are key components of ICSS.

ICSS enables real-time monitoring, regulation, and response to dynamic industrial processes.

Industries such as manufacturing, energy management, water treatment, transportation, and healthcare extensively utilize ICSS.

Implementing ICSS leads to improved process optimization, operational stability, regulatory compliance, and enhanced safety.

Introduction to Integrated Control & Safety Systems (ICSS)

Integrated Control & Safety Systems (ICSS) are vital in modern industrial automation. They ensure safe, efficient, and reliable operation of complex processes. ICSS combines hardware, software, and communication networks to monitor and control industrial facilities.

These systems are crucial in oil and gas, chemical, power generation, and manufacturing plants. They optimize plant performance and minimize risks through real-time data collection and analysis.

ICSS incorporates various technologies for comprehensive process management. These include wearable sensors, environmental monitoring sensors, and human-machine interfaces (HMIs). Distributed control systems (DCS) are also integral to ICSS functionality.

Definition & Purpose of ICSS

ICSS is a comprehensive set of interconnected systems for industrial process management. It prioritizes safety, reliability, and efficiency in operations. The primary goals of ICSS are process control, safety assurance, and production optimization.

Monitor and control process variables

Ensure the safety of personnel, equipment, and the environment

Optimize production and minimize downtime

Facilitate data collection and analysis for continuous improvement

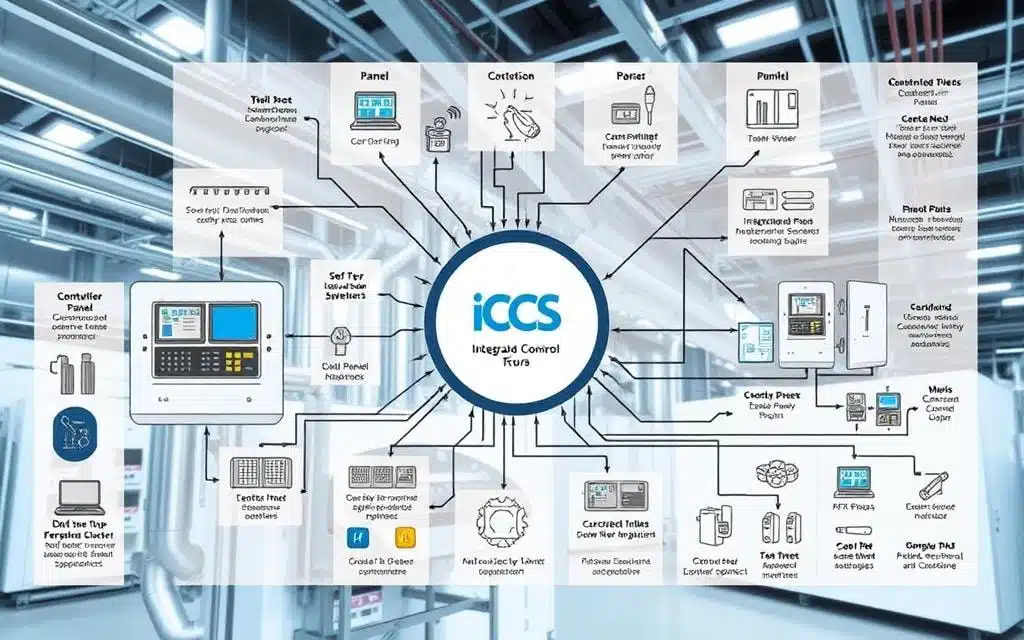

Key Components of ICSS

Several key components work together in ICSS to achieve its objectives:

Sensors and field devices: These include wearable sensors, environmental monitoring sensors, and other instrumentation that collect real-time data from the process.

Programmable Logic Controllers (PLCs): PLCs are the backbone of ICSS, executing control logic and managing input/output signals.

Human-Machine Interfaces (HMIs): HMIs provide a user-friendly interface for operators to monitor and interact with the system.

Distributed Control Systems (DCS): DCS are responsible for process control, data acquisition, and supervisory functions.

Communication networks: Robust and secure sensor networks enable seamless data exchange between various ICSS components.

Remote Terminal Units (RTUs): RTUs are microprocessor-controlled field devices that receive commands and send information back to a master terminal unit (MTU). They aid in data acquisition and control by interfacing with local sensors and actuators.

Component | Function |

|---|---|

Sensors | Collect real-time data from the process |

PLCs | Execute control logic and manage I/O signals |

HMIs | Provide user interface for monitoring and interaction |

DCS | Handle process control, data acquisition, and supervision |

Networks | Enable data exchange between ICSS components |

RTUs | Receive commands and send information back to MTU, interface with local sensors and actuators |

The Importance of ICSS in Industrial Automation

ICSS is crucial in modern industrial automation. It enhances safety by preventing accidents and minimizing risks. The system improves efficiency through process optimization and downtime reduction.

Enhancing safety: ICSS helps prevent accidents, minimize risks, and protect personnel, equipment, and the environment.

Improving efficiency: By optimizing processes and reducing downtime, ICSS contributes to increased productivity and cost savings.

Enabling data-driven decision-making: ICSS collects and analyzes valuable data, facilitating informed decision-making and continuous improvement.

The implementation of ICSS has revolutionized industrial automation, providing a comprehensive approach to process control, safety, and optimization.

Industries face new challenges as they evolve. ICSS will grow in importance for ensuring safe, efficient, and sustainable operations. Its role in industrial automation continues to expand and adapt.

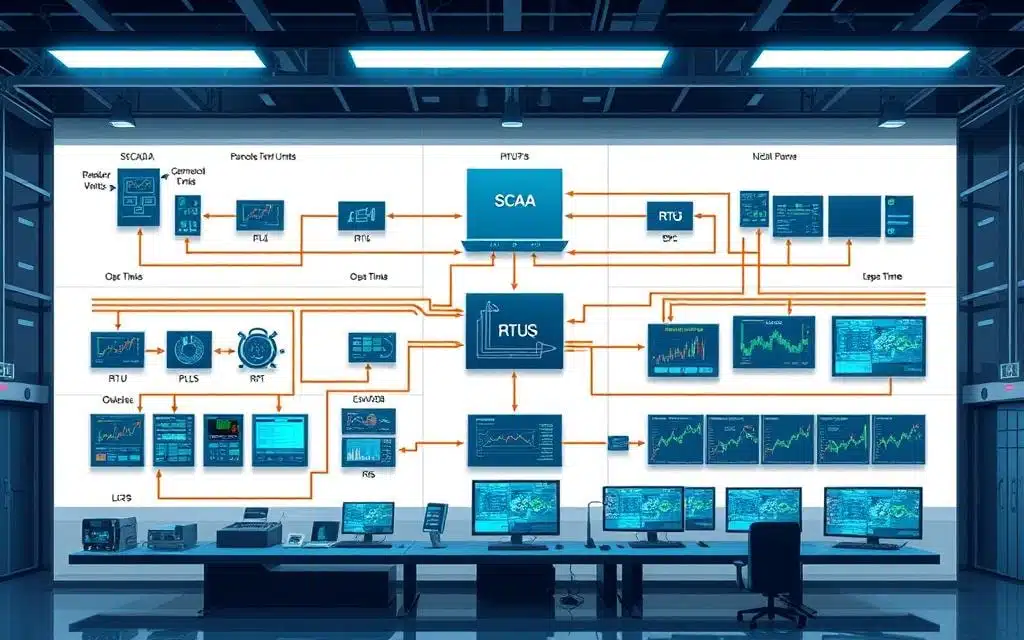

Understanding Supervisory Control & Data Acquisition (SCADA) Systems

SCADA systems are the cornerstone of modern industrial automation. They monitor, gather, and process real-time data from remote locations. These systems interact with devices like sensors and motors through Human-Machine Interface software. Supervisory control software plays a crucial role in SCADA systems by managing and controlling various operational tasks, enabling centralized monitoring and command issuance to field devices. This enables seamless control and supervision of industrial processes.

Industries like oil and gas, power generation, and manufacturing rely heavily on SCADA systems. They streamline operations, reduce manual intervention, and ensure rapid problem resolution. Real-time data collection and analysis help identify and fix issues promptly. This minimizes downtime and enhances operational efficiency.

The Benefits of SCADA Systems

SCADA systems offer numerous advantages to organizations. These include cost savings, enhanced safety, and consistent product quality. They also increase productivity, offer scalability, and provide customization options. SCADA systems allow plant managers to access production and operation data for analysis and decision-making, optimizing industrial processes.

Cost savings through reduced downtime, energy optimization, and process inefficiency identification

Enhanced safety by real-time monitoring of critical parameters and early hazard detection

Consistent product quality through automated process control and deviation correction

Increased productivity by reducing manual labor and accelerating processes

Scalability to accommodate fluctuating process or equipment needs

Customization to meet specific organizational requirements

Extensive data storage, analysis, and reporting capabilities for detailed insights

SCADA Architecture & Evolution

SCADA systems have evolved through four distinct generations. They started with monolithic systems and progressed to distributed, networked, and web-based systems. Modern SCADA systems offer enhanced scalability, interoperability, and vendor support compared to legacy systems.

“The evolution of SCADA systems has been driven by the need for greater flexibility, scalability, and interoperability in industrial automation. Modern SCADA solutions leverage open system architectures and non-vendor-specific communication protocols to enable seamless integration and data access across the enterprise.”

Addressing Cybersecurity Concerns in SCADA Systems

SCADA systems face increasing cybersecurity threats due to remote access and internet connectivity. The Schneider Electric hack exemplifies this risk. Attackers gained control of the company’s emergency shutdown system. Robust security measures are crucial to safeguard critical networks.

Organizations must prioritize cybersecurity in their SCADA implementations. Best practices include secure communication protocols, regular security audits, and employee training. These measures help mitigate potential risks and protect vital industrial systems.

SCADA systems have transformed industrial automation, offering enhanced control and efficiency. Embracing modern technologies and addressing cybersecurity concerns is vital. This approach unlocks SCADA’s full potential in driving industrial growth and innovation.

Distributed Control Systems (DCS) in ICSS

Distributed Control Systems (DCS) are vital in Integrated Control & Safety Systems (ICSS). They manage complex industrial processes across various sectors. DCS controls distributed processes individually, ensuring efficient operations in manufacturing, power generation, and more.

DCS uses a network of smart sensors, controllers, and communication protocols. It gathers real-time data from the plant floor for precise control. Advanced sensor fusion techniques combine data from multiple sensors for comprehensive plant operation insights.

Key Components of DCS

The key components of a Distributed Control System include:

Distributed Control Units (DCUs)

Human-Machine Interface (HMI)

Programmable Logic Controllers (PLCs)

Communication Network

Centralized Supervisory Control Loop

These components facilitate seamless data exchange and control across sensor networks. The centralized supervisory control loop plays a crucial role in managing multiple local controllers and devices within industrial processes. It enables operators to access and analyze production and operational data efficiently, thereby enhancing decision-making and system resilience against single-point failures. They enable operators to effectively monitor and manage industrial processes.

Advantages of Using DCS in ICSS

Implementing DCS in ICSS offers several significant advantages, including:

Enhanced process control efficiency

Improved flexibility in adapting control strategies

Comprehensive data integration from various sensors and devices

Increased scalability and modularity

DCS enables organizations to optimize their industrial processes, reduce downtime, and improve overall operational efficiency.

DCS systems are generally proprietary in nature. Replacement hardware, software, and parts must be ordered from the original vendor. This can lead to higher costs compared to other Industrial Control Systems.

System | Real-time Interaction | Scope |

|---|---|---|

DCS | High | Localized |

SCADA | Limited | Large-scale |

The Role of Programmable Logic Controllers (PLCs) in ICSS

PLCs are vital components of Integrated Control and Safety Systems (ICSS). They automate and control various industrial processes. PLC supervisory control software plays a crucial role in managing and controlling local operations within SCADA and DCS systems, providing supervisory commands to field devices and facilitating data communication between various control components. These devices are widely used in manufacturing, power generation, and water treatment sectors.

What are PLCs?

PLCs are digital computers designed for controlling industrial operations. They consist of input modules, a central processing unit (CPU), and output modules. PLCs monitor sensor inputs, including internet of things sensors, wearable sensors, and environmental monitoring sensors.

They execute pre-programmed control algorithms to manage various industrial processes. PLCs handle tasks like motor control, assembly lines, and simple machinery operations.

The global Industrial Control Systems (ICS) market, which includes PLCs, is growing rapidly. Projections indicate it will reach $23.5 billion by 2026. This growth highlights the increasing importance of PLCs in industrial environments.

PLC Programming Languages & Logic

PLCs support various programming languages, including:

Ladder Logic

Structured Text

Function Block Diagrams

Sequential Function Charts

These languages allow engineers to customize control logic for specific industrial needs. PLCs adhere to standards like IEC 61131-3. This standard defines programming languages and ensures interoperability among different PLC brands.

Advantages of Using PLCs in ICSS

PLCs offer several advantages in ICSS:

Automation of repetitive tasks

Flexibility in modifying control logic

Reliability in harsh industrial environments

Seamless integration with other ICSS components

Real-time monitoring and control capabilities

PLCs have become the backbone of modern industrial automation, enabling precise control and monitoring of processes, leading to increased efficiency and productivity.

The following table highlights the key differences between PLCs and other control systems:

Control System | Application | Programming | Scalability |

|---|---|---|---|

PLC | Discrete manufacturing, assembly lines | Ladder logic, structured text | Modular, easily expandable |

DCS | Continuous process control | Function block diagrams | Centralized, limited scalability |

SCADA | Supervisory control, data acquisition | Graphical user interfaces | Distributed, highly scalable |

PLCs continue to evolve with industry advancements. They enable seamless integration of internet of things sensors, wearable sensors, and environmental monitoring sensors into ICSS. This integration enhances data collection and real-time monitoring.

As a result, PLCs contribute to optimized control strategies. They ultimately improve operational efficiency and safety in industrial environments.

Safety Instrumented Systems (SIS) & Emergency Shutdown Systems (ESD)

Safety Instrumented Systems (SIS) and Emergency Shutdown Systems (ESD) are vital for industrial automation safety. These critical components detect abnormal conditions and initiate safety measures. They prevent accidents and minimize risks in Integrated Control & Safety Systems (ICSS).

SIS and ESD systems have evolved over decades. They now offer high-speed logic processing and high reliability. Modern safety systems also provide predictable failure modes, essential for maintaining safe industrial environments.

The Purpose of SIS & ESD

SIS monitors critical process variables and activates fail-safe protection when hazards arise. It ensures compliance with safety standards like ANSI/ISA 84 and NFPA. ESD systems rapidly shut down industrial processes during emergencies.

Key Components of SIS & ESD

SIS and ESD systems comprise several key components working together for plant safety. These include:

Sensors and detectors for monitoring process variables

Logic solvers for processing safety-related data

Final control elements, such as valves and switches, for implementing safety actions

Human-Machine Interfaces (HMIs) for operator interaction and monitoring

Programmable Logic Controllers (PLCs) for executing safety logic

These components are designed with built-in redundancy and self-testing capabilities. They provide reliable and efficient safety functions in industrial settings.

Ensuring Plant Safety with SIS & ESD

Implementing SIS and ESD systems requires careful planning and execution. Competence in electrical, control, and instrumentation disciplines is crucial. Quality procedures and information control are essential for project success.

Features & Benefits | |

|---|---|

ProSafe-RS Lite | Conforms to international safety standards for up to SIL2 applications |

ProSafe-RS | Offers dual architecture in every module for control system integration |

ProSafe-SLS | Provides the highest-integrity, SIL4-rated applications with self-testing technology |

Sustainable SIS | Software-based solution for optimizing process safety with optimum OPEX throughout the safety lifecycle |

Advanced technologies like Yokogawa’s ProSafe-RS and Sustainable SIS ensure high safety levels. With the right SIS, ESD, and ICSS components, plants can minimize risks. They can comply with safety standards and protect their most valuable assets.

Fire & Gas Detection Systems (F&G) in ICSS

F&G systems are crucial for safety in industrial settings. They monitor flammable gases, toxic gases, and fires within facilities. These systems use Honeywell smart sensors to provide early warnings and trigger mitigation actions when hazards arise.

Modern F&G systems integrate with ICSS components like ESD and DCS. This integration minimizes interventions and shutdowns, reducing hardware costs. It also aids in recovery from process upsets. Implementing an ICSS platform can lower operation and maintenance costs significantly.

F&G systems must adhere to industry standards like IEC 61511. This standard protects industrial plants through Risk Reduction Measures. Professionals can enhance their expertise with the FGP course, a certified training program in F&G technology.

Comprehensive F&G systems include various detection technologies. These range from flame detection to smoke and heat detection. Gas detection methods include catalytic bead, toxic gas detection, and open path laser.

Flame Detection (UV, UV/IR, IR, IR3, Visual)

Smoke and Heat Detection

Gas Detection (Catalytic Bead, Toxic Gas Detection, Semi-Conductor Sensor Point, Electrochemical Cell, Open Path Laser, IR Gas Detection, Ultrasonic Gas Detection)

These systems meet international standards like IEC 61508 SIL2, NFPA 72, and EN54. By integrating with SCADA systems, they provide real-time monitoring. This ensures high levels of cybersecurity and personnel safety in industrial environments.

System | Key Features |

|---|---|

Addressable Fire Detection System (AFDS) | Initiates fire and gas alarms, interfaces with ICSS and SIS via Modbus |

High Sensitivity Smoke Detection System (HSSD) | Early fire detection in server rooms and control panels, meets EN54 and NFPA 72 |

Fire Protection System | Includes Sprinkler Systems, Water Deluge Systems, Dry Chemical Systems, Wet Chemical Systems, and Gas Fire Suppression Systems (FM 200, Inergen, CO2) |

Fire Damper Control System | Controls and monitors fire dampers in HVAC ducts for passive fire protection |

Fixed Gas Sampling System | Continuous gas level monitoring, single-point or multi-point, ATEX Certified for hazardous areas (Zone 1) |

Human-Machine Interfaces (HMIs) & Operator Stations

Human-Machine Interfaces (HMIs) are crucial in Integrated Control & Safety Systems (ICSS). They bridge operators and complex industrial processes. HMIs display real-time data from sensor networks and Internet of Things (IoT) sensors. This enables effective monitoring and interaction with the process.

Human-machine interaction has evolved significantly over time. It progressed from batch processing to command line interfaces, and then to Graphical User Interfaces (GUIs). Today’s advanced HMIs allow remote control of multiple machines across various sites. This advancement boosts efficiency and reduces costs in industrial settings.

The Role of HMIs in ICSS

HMIs are vital in various industrial control systems. These include SCADA, DCS, and PLC systems. In these setups, HMIs display data from controllers and enable user input for process control.

SCADA systems heavily rely on embedded HMI components. They monitor and control large-scale processes over long distances. This reduces the need for human intervention in industrial operations.

Designing Effective HMI Screens

Effective HMI design is crucial for efficient process control and operator performance. Key considerations include clear information hierarchy and consistent navigation. Using color and contrast for readability is also important.

Minimizing visual clutter and providing relevant, timely information are essential. Well-designed HMI screens allow operators to interpret data quickly. This enables informed decision-making and prompt responses to alarms or abnormal situations.

Best Practices for HMI Usability & Ergonomics

HMIs should follow established usability and ergonomic principles. This ensures optimal operator performance and reduces error risk. Best practices include maintaining consistent layouts and using clear labeling.

Best Practice | Description |

|---|---|

Consistent layout | Maintain a consistent layout across screens to reduce cognitive load |

Clear labeling | Use clear and concise labels for buttons, icons, and data points |

Appropriate text size | Ensure text is large enough to be easily readable from a distance |

Accessible controls | Place frequently used controls within easy reach of the operator |

As industrial processes grow more complex, HMIs play a crucial role in data integration. They incorporate information from various sources, including sensor fusion systems. Leveraging advanced technologies and following best practices optimizes control and safety systems.

Industrial Networks & Communication Protocols

Industrial networks and communication protocols form the backbone of Integrated Control & Safety Systems (ICSS). They enable seamless data exchange and control commands among various components. These networks are designed for reliability, security, and resilience in harsh industrial settings.

Selecting the right protocol depends on data transfer rate, network topology, and specific industrial application needs. Fieldbus protocols like HART, PROFIBUS, Modbus, and Foundation Fieldbus reduce wiring costs and improve data quality. Wireless protocols offer greater range and simpler implementation compared to wired methods.

Ethernet-based protocols, such as EtherNet/IP and PROFINET, provide high-speed, reliable communication for industrial control systems. They leverage Ethernet’s ubiquity while incorporating features tailored for industrial applications. Internet protocols enable data sharing, cloud computing, and IoT applications, expanding ICSS capabilities.

Serial protocols remain relevant for low-cost devices with limited processing power and bandwidth needs. Hybrid protocols combine features from different types to meet specific industrial control system requirements. CIP (Common Industrial Protocol) is widely used in automating industrial operations and ensuring smooth device interaction.

Modbus, a commonly used industrial communication protocol, facilitates client-server mode communication across different types of equipment, even when linked through various underlying technologies.

The integration of wearable sensors and environmental monitoring sensors has expanded ICSS data collection and analysis. These sensors, coupled with advanced HMI systems, enable real-time monitoring and control of industrial processes. This enhances safety, efficiency, and decision-making capabilities.

Protocol | Application | Key Features |

|---|---|---|

Modbus | Industrial automation, DCS | Client-server communication, simple and widely supported |

DNP3 | SCADA systems, utilities | Reliable communication, error detection, time-stamping |

PROFINET | Industrial automation, real-time control | High-speed communication, deterministic performance |

ICSS networks increasingly integrate with cloud, IoT, and remote IT systems, creating new security challenges. Robust network infrastructure and cybersecurity measures are crucial for maintaining ICSS integrity and availability amid evolving threats.

Types of ICSS: An Overview

Integrated Control & Safety Systems (ICSS) are vital in industrial automation. They ensure optimal operation, risk management, and safety. These systems are tailored to specific industrial applications, addressing unique challenges and requirements.

Integrated Control & Safety Systems (ICSS)

ICSS combines control and safety functions into a unified system. It integrates industrial control systems (ICS) such as SCADA, DCS, and PLCs. This integration enables seamless communication between process control and safety instrumented systems.

ICSS enhances plant efficiency and reduces downtime. It also minimizes the risk of accidents or incidents. The system’s comprehensive approach improves overall industrial operations.

Process Safety Systems (PSS)

PSS prevent and mitigate process-related hazards in high-risk industries. They incorporate safety instrumented systems, emergency shutdown systems, and fire and gas detection systems. These components safeguard personnel, assets, and the environment.

PSS continuously monitor process parameters. They initiate automatic actions when safety thresholds are exceeded. This proactive approach helps maintain a safe working environment.

Burner Management Systems (BMS)

BMS are specialized ICSS solutions for combustion processes. They’re crucial in oil and gas, power generation, and chemical manufacturing. BMS integrate flame detectors, fuel valves, and ignition systems.

These systems control and monitor burner operations. BMS implement strict safety interlocks and sequences. They prevent hazardous conditions like fuel leaks, flashbacks, or uncontrolled combustion.

ICSS is crucial in managing complex industrial processes. It provides a robust framework for risk management and operational optimization. ICSS leverages technologies like SCADA, DCS, and PLCs for real-time monitoring and control.

This system empowers operators to make informed decisions. It enables prompt responses to potential hazards. ICSS enhances safety measures and operational efficiency in modern industrial settings.

Conclusion

Integrated Control & Safety Systems (ICSS) are crucial for optimizing operations and ensuring safety in modern industries. They integrate SCADA, DCS, PLCs, SIS, ESD, F&G, and HMIs to boost efficiency and reliability. As IT and OT systems merge, robust cybersecurity measures become increasingly vital.

Smart sensors and sensor fusion have transformed data collection and analysis in industrial systems. These advancements enable intelligent decision-making, predictive maintenance, and improved operational visibility. However, the growing reliance on these technologies demands comprehensive cybersecurity strategies.

The future of ICSS lies in integrating AI, machine learning, and IoT technologies. These advancements offer opportunities for growth, innovation, and sustainability in industrial organizations. To fully leverage these technologies, prioritizing cybersecurity and developing robust frameworks is essential.

ICSS shapes the future of industrial automation. Understanding its components and best practices helps organizations navigate modern industrial complexities. Moving forward, fostering continuous learning, collaboration, and innovation is key to driving success in industrial operations.

FAQ

What are the main components of an Integrated Control & Safety System (ICSS)?

ICSS key components include sensors, programmable logic controllers (PLCs), human-machine interfaces (HMIs), and communication networks. These elements collaborate to monitor and control operational technology (OT) systems. They ensure safety and efficiency in industrial operations.

How do SCADA systems contribute to industrial automation?

SCADA systems offer supervisory-level control, monitoring real-time data from remote locations. They interact with devices like sensors and motors through HMI software. This enables long-distance monitoring and control of field sites across various industries.

What are the benefits of using Distributed Control Systems (DCS) in ICSS?

DCS improves process control efficiency and flexibility in adapting control strategies. It integrates data from various sensors and devices across the plant. Operators can efficiently manage complex processes from a centralized location.

How do Programmable Logic Controllers (PLCs) automate industrial processes?

PLCs automate electromechanical processes through logic, sequencing, and control functions. They monitor sensor inputs and execute control algorithms to manage industrial processes. PLCs offer automation of repetitive tasks and flexibility in modifying control logic. They also provide reliability in harsh industrial environments.

What is the role of Safety Instrumented Systems (SIS) and Emergency Shutdown Systems (ESD) in ICSS?

SIS and ESD are crucial ICSS components that detect abnormal conditions and initiate safety measures. SIS monitors process variables and activates fail-safe protection when hazards are identified. ESD systems rapidly shut down industrial processes during emergencies to minimize risks.

How do Fire and Gas Detection Systems (F&G) contribute to safety in industrial environments?

F&G systems monitor flammable gases, toxic gases, and fires within facilities. They activate alarms and initiate mitigation actions when hazards are detected. These systems ensure early hazard detection, personnel safety, and asset protection.

What are the best practices for designing effective Human-Machine Interfaces (HMIs) in ICSS?

Effective HMI design is crucial for efficient process control and operator performance. Best practices include clear information hierarchy and consistent navigation. Adhering to ergonomic principles ensures operators can easily monitor and control industrial processes.

What are the common industrial communication protocols used in ICSS?

Common industrial communication protocols in ICSS include Modbus, Profibus, and Ethernet/IP. These protocols enable data exchange and control commands between various components. They form the backbone of robust and secure industrial networks.

What are the different types of ICSS tailored to specific industrial applications?

ICSS includes various systems like Integrated Control & Safety Systems combining control and safety functions. Process Safety Systems (PSS) focus on preventing and mitigating process-related hazards. Burner Management Systems (BMS) ensure safe and efficient operation of combustion processes.

Why is cybersecurity critical for the success and resilience of industrial operations in ICSS?

As technology advances, robust cybersecurity measures become crucial for industrial operations. ICSS must be protected against cyber threats to ensure system integrity. This safeguards the availability and confidentiality of industrial systems and data.

3 thoughts on “Types of ICSS: An Integrated Control & Safety Systems Guide”

Comments are closed.