In the competitive realms of SCADA industry, efficiency is the keystone of triumph. With a SCADA system, an acronym for Supervisory Control and Data Acquisition, a revolutionary shift in industrial automation is underway. These systems are central to optimizing data collection, managing control equipment operations, and boosting significant savings in both time and costs.

The essence of SCADA integration lies in its flawless communication with numerous devices. The influence of SCADA systems stretches beyond immediate benefits, propelling businesses towards sustainable growth. Envision an environment where machines are intelligent partners, decision-making is inspired by data, resources are used efficiently, and savings naturally follow.

A significant shift is observed across various sectors, all benefiting from SCADA systems. Wind farms, for instance, see a decrease in on-site visits thanks to remote oversight. Manufacturing units refine their operations, enhancing efficiency at every step. Join us in exploring how SCADA is redefining industrial automation’s future landscape.

Key Takeaways

Insight into how SCADA systems excel in optimizing industrial automation across multiple sectors.

Understanding the importance of SCADA integration in realizing substantial time and cost savings.

Exploration of different industries where SCADA is pivotal for enhancing operational efficiency.

Assessment of the long-term strategic benefits SCADA systems offer for smart resource management.

Recognition of SCADA’s role in advanced data analytics for informed decision-making processes.

Understanding the Fundamentals of SCADA

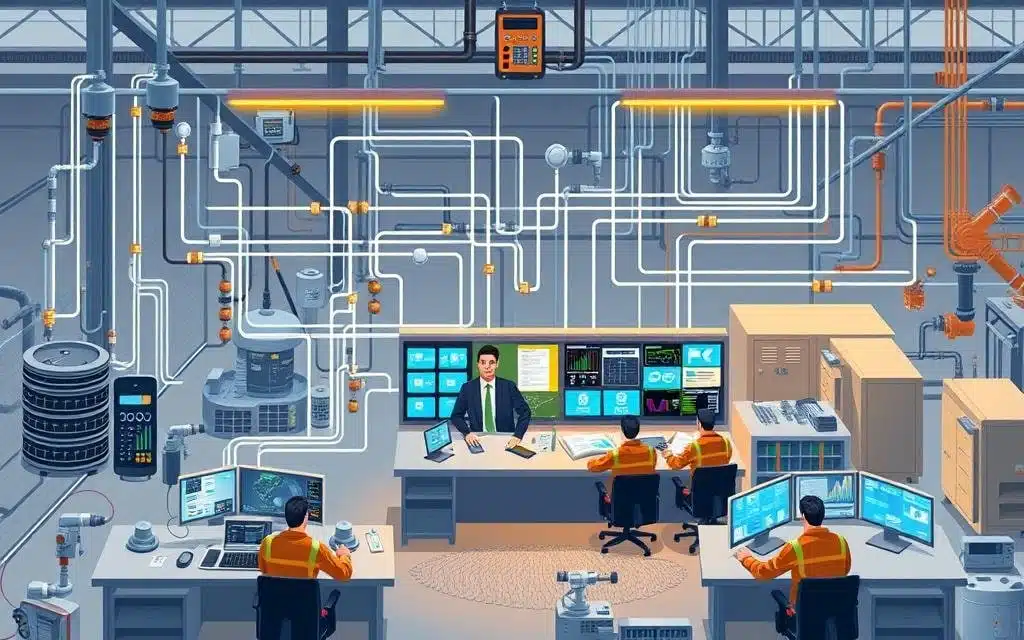

SCADA systems are pivotal in elevating operational efficiency and reliability in various industries. Distributed SCADA systems, which emerged in the 80s and 90s, relied on interconnected systems and marked a transition from monolithic to more advanced setups, despite challenges in interoperability due to proprietary LAN protocols. They integrate advanced hmi SCADA interfaces, plc SCADA frameworks, and dynamic data acquisition methods. Modern SCADA systems further enhance organization efficiency and decision-making by leveraging real-time data access and modern IT standards, offering improved performance, security, and productivity over legacy systems. This provides unmatched monitoring and control.

What Is SCADA?

SCADA stands as a complex system that gathers, analyzes, and responds to data from different industrial processes. It facilitates remote equipment management using hardware like PLCs (Programmable Logic Controllers) and RTUs (Remote Terminal Units). Software systems display this data via human machine interface (HMI), achieving peak operational efficiency with minimal downtime.

Core Components of a SCADA System

Function

| Component | Function |

|---|---|

| Sensors | Collect crucial data such as temperature and pressure. |

| Actuators | Execute actions based on SCADA commands, like opening valves. |

| RTUs | Digitize sensor data and send it to the central SCADA system. |

| PLCs | Automate control processes through conditional responses. |

| HMI | Allow operators to interact with the SCADA system, monitoring processes and making adjustments as needed. |

| Communication Protocols | Standardize data transmission using protocols like Modbus and DNP3, ensuring system interoperability and efficiency. |

The Role of Supervisory Control in Industrial Automation

Supervisory control is the operational brain, driving automated processes while prioritizing safety and accuracy. SCADA systems deliver real-time data for swift, informed decisions by operators. This prevents system failures and hazards. With hmi SCADA technology advancements, supervisory control has become more interactive and accessible. It fosters a more dynamic, responsive industrial setting.

The Versatile Applications of SCADA Systems

SCADA systems have been transformative since the 1960s, especially in industries such as oil and gas, power distribution, and water management. They started with pipeline monitoring in the oil sector. Yet, their influence has expanded across various fields, including transportation and renewable energy sectors.

SCADA systems are pivotal in digital transformation and industrial automation. They offer advanced monitoring and automation, enhancing efficiency in different industries. Within the renewable energy sector, they optimize output from resources like solar PV plants and wind turbines. This ensures effective energy production and its subsequent distribution.

Transportation benefits from SCADA by integrating with diverse technologies. This integration improves traffic systems and bridges communication in railway networks, boosting both safety and operational efficiency. Water management relies on SCADA to track and manage everything from water flow to purification processes. Such monitoring confirms the optimal distribution of safe water.

| Industry | Application of SCADA | Benefits |

|---|---|---|

| Power Distribution | Grid management, fault detection | Enhanced reliability, reduced outages |

| Oil and Gas | Pipeline monitoring, leak detection | Improved safety, mitigated environmental impacts |

| Water Management | Monitoring water quality, control over distribution | Efficient use of resources, meets safety norms |

| Renewable Energy | Power output optimization | Increased energy production, focuses on sustainability |

| Transportation | Management of traffic and railways | Enhanced traffic flow, heightened public safety |

SCADA systems extend beyond mere monitoring and control. They generate valuable data that influences decision-making. This data allows for predicting potential system failures, effectively scheduling maintenance, and cutting down operational costs. Integrating IoT and cloud technology, SCADA is a linchpin of Industry 4.0. It’s set to enhance industrial operations with unmatched automation and instant insights.

In the journey through the digital era, SCADA’s importance in renewable energy, water management, and transportation is skyrocketing. Leveraging SCADA enables not just better management but also technological adaptation. It underscores its critical role in today’s industrial automation landscape.

How SCADA Enhances Operational Efficiency

In the industrial arena, boosting efficiency alongside reliable production is crucial. SCADA software solutions are at the vanguard of transforming operations. It introduces robust solutions for better automated reporting and management of production.

Streamlining Production Processes

SCADA systems merge advanced tech with user-friendly interfaces. They offer insights in real-time that make production smoother. Operators can optimize operations and adapt parameters instantly. This ensures productivity stays high without compromising quality.

The real-time updates from SCADA are key in keeping operations efficient. They guarantee that production flows smoothly, meeting the required standards.

Data-Driven Decision Making with SCADA

Data, the industrial goldmine, is fully leveraged by SCADA systems for smarter decision-making. They come with SQL databases and web apps, providing deep analytical tools. These tools help in analyzing data extensively. Thus, operators can decide better ways to boost output and cut costs.

Reducing Downtime & Maintenance Costs

Downtime spells loss and higher maintenance expenses for industries. SCADA’s real-time alerts and diagnostics offer a solution. They detect issues early, reducing emergency fixes. This curtails costs and prolongs equipment life.

This immediate feedback from SCADA elevates operational lifespan and sustainability. It represents a shift towards proactive maintenance.

The shift from single-unit to networked SCADA systems marks a technological and needs-based evolution. These interconnected systems result in better efficiency and profitability. SCADA’s advancement is crucial for enhancing and rejuvenating industrial operations dynamically.

The Architecture of SCADA Networks Explained

SCADA networks play a vital role in industrial automation through their complex structure. This structure aims to boost communication and operational effectiveness. At its heart is the integration of various elements, like PLCs (Programmable Logic Controllers) and RTUs (Remote Terminal Units), along with advanced communication techniques. The architecture’s modularity not only allows for growth but also bolsters dependability and managerial capabilities in industrial contexts.

Connectivity & Communication Protocols

A SCADA system’s connectivity largely depends on various communication protocols such as OPC UA, Modbus, and EtherNet/IP. These ensure a consistent flow of data throughout the network. These protocols are key for strong communication between the control center and field devices. They enable the transfer of data, both in real-time and asynchronously. Grasping and applying these protocols well is crucial for optimizing SCADA networks. This allows them to manage a wide range of industrial activities, each with their unique challenges.

Role of PLCs & RTUs in SCADA

In the structure of SCADA systems, PLCs and RTUs hold significant positions. PLCs mainly automate control tasks by converting sensor outputs into actionable data. On the other hand, RTUs collect data from sensors and send it to the supervisory system, serving as essential connectors. These elements are the foundation of SCADA networks. They enable key operations such as gathering data, monitoring the system, and managing hardware.

Interface & Data Visualization with HMI SCADA

Human Machine Interfaces (HMIs) are at the forefront of SCADA systems, facilitating interaction between humans and processes. HMI SCADA systems bring dynamic visualization tools to the table, aiding in the oversight and management of automated functions. This interface lets operators view intricate diagrams of controlled procedures. It simplifies complicated tasks and aids decision-making through detailed graphical depictions and live data feedback.

To delve deeper into how advanced SCADA systems revolutionize industrial settings, visit how digital transformation influences customer experiences.

Additionally, a data historian holds a key spot within SCADA networks by storing important operational data. This is vital for analyzing trends and improving predictive maintenance strategies. Such strategies are critical for reducing downtime and prolonging the service life of industrial assets.

In closing, SCADA networks’ modular design, coupled with intricate communication protocols and strategic implementation of PLCs, RTUs, and HMIs, form an effective infrastructure. This is essential for cutting-edge industrial automation. By adapting and incorporating these technologies, industries can achieve greater efficiency and reliability in their procedures.

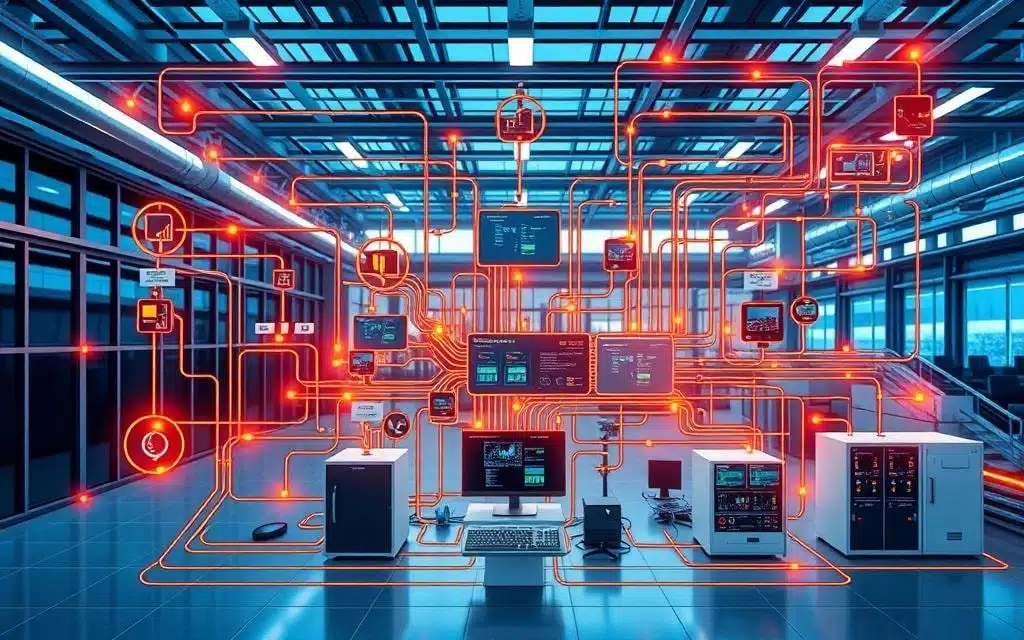

Ensuring Security in SCADA Networks

Industrial control systems, such as SCADA networks, play a crucial role in global industry operations. Yet, they face escalating cyber threats. Effective scada security requires a combination of risk management and asset management. This approach ensures the reliability and security of these essential systems.

Challenges & Solutions for SCADA Security

SCADA systems face challenges like outdated protocols and vulnerabilities to cyberattacks. The attack on Pennsylvania’s Municipal Water Authority of Aliquippa highlights these risks. It emphasizes the need for enhanced security in industrial control systems.

Implementing Robust SCADA Security Measures

Organizations need to enact comprehensive security measures to protect SCADA systems. This includes cyber and physical safeguards. Network segmentation, strict access controls, and ongoing monitoring are key to this defense.

| Security Measure | Description | Impact |

|---|---|---|

| Multi-factor Authentication | Requires multiple forms of verification to gain system access | Enhances barrier against unauthorized access |

| Regular Software Updates and Patch Management | Ensures all systems are up-to-date and secure against known vulnerabilities | Reduces the risk of cyber exploits |

| Comprehensive Network Segmentation | Divides the network into distinct zones, each managed separately to contain potential breaches | Limits the spread of breaches, enhancing overall system security |

| Incident Response Plans | A structured approach to address and manage the aftermath of a security breach | Reduces recovery time and mitigates potential damage |

| Employee Training | Regular training on cybersecurity best practices | Builds a knowledgeable workforce capable of responding to security challenges effectively |

Integrating these strategies within a cybersecurity framework protects scada systems against threats. Adherence to security standards, as outlined in the 21 steps to improve cybersecurity, is vital. Through proactive risk management and asset management, a secure environment for SCADA networks is achievable.

Integration of SCADA with Other Industrial Systems

Industries are migrating into the era of Industry 4.0, marked by intelligent systems and greater network connectivity. This shift makes integrating SCADA systems with other technologies crucial. It bolsters data-driven operations and enhances asset management, both vital across sectors like utilities and manufacturing.

Linking SCADA with Computerized Maintenance Management Systems (CMMS) is a case in point. By relaying data from SCADA, such as equipment runtimes, to CMMS, companies can adopt anticipatory maintenance approaches. This approach guarantees maintenance activities are initiated based on live data. It not only extends the operational lifespan but also improves asset management accuracy.

Further, integrating SCADA boosts more than operational productivity; it ensures information flows smoothly across platforms. Integration allows using IoT for better energy management or advanced analytics for immediate decision-making. For example, connecting SCADA with IoT platforms like GE’s Predix or Siemens MindSphere can bring considerable cost reductions and operational efficiencies.

Employing MQTT, REST, and SOAP protocols guarantees reliable and secure data exchange between SCADA and various systems.

Middleware like MuleSoft and IBM Integration Bus streamlines complex data interactions, enhancing SCADA’s connectivity with ERP and BI systems.

Cloud solutions from Amazon Web Services boost SCADA effectiveness by providing scalable data storage that meets industrial demands.

Boosting SCADA through integration not only enriches data-driven operations but also strengthens infrastructure resilience and flexibility. The strategic utilization of cutting-edge platforms enables detailed monitoring and control. This leads businesses to never-before-seen levels of operational efficiency and asset management agility.

Real-World Success Stories: SCADA in Action

In various industries, SCADA systems have been pivotal in boosting operational efficiency and decision-making capabilities. We will explore impactful SCADA case studies in manufacturing and renewable energy. These stories highlight the transformational role of SCADA International and its acclaimed OneView® SCADA software.

Case Studies of SCADA in Manufacturing

In manufacturing, PTSG’s SCADA solutions offer real-time monitoring and data analysis. This enhances operational flexibility. These systems provide strategic control for agility and informed decision-making. This has led to reduced downtime and increased productivity, as seen in multiple real-world examples.

SCADA Systems in Renewable Energy Management

SCADA plays a transformative role in renewable energy, especially in photovoltaic plants. Its resilience minimizes downtime and maximizes power generation, even amidst adverse weather. Advanced monitoring systems allow for preemptive maintenance and issue prevention. This ensures uninterrupted energy production.

SCADA International's Impact on Industrial Automation

SCADA International leads in merging SCADA systems with AI and IoT. This boosts automation and data-based decision-making across fields. Their flagship product, OneView® SCADA, redefines industrial control and efficiency. This fosters adherence to Industry 4.0 and propels industries towards a smarter environment.

The impact of SCADA’s advanced systems goes beyond operational control. They incite a shift toward innovation and adaptability, preparing industries for upcoming challenges.

To grasp these systems’ effectiveness and scope, consider this comparative analysis:

| Feature | SCADA in Manufacturing | SCADA in Renewable Energy |

|---|---|---|

| Real-time Monitoring & Control | Enhanced | Critical for Continuous Operation |

| Operational Efficiency | Significantly Improved | Optimized During Adverse Conditions |

| Data-Driven Decision Making | Actionable Insights for Strategic Control | Real-Time Data Aids in Preemptive Maintenance |

| Integration with AI & IoT | Aligns with Industry 4.0 Standards | Enhances Automation and Monitoring |

| Cybersecurity | Robust Measures Integrated | Ensures Safety and Confidentiality of Data |

The table not only shows SCADA systems’ unique benefits in these sectors but also the adaptability of solutions from SCADA International. These case studies demonstrate how advanced technology, and its application revolutionize today’s industrial landscape.

Choosing the Right SCADA Software for Your Business

Integrating SCADA software into your business operations requires choosing a solution that matches your needs. This choice affects the efficiency and longevity of your operations significantly. The choice is essential, as noted by experts in selecting the right SCADA system. Among the options available, OneView® SCADA shines. It provides deep insights and simplifies complex data management through superior data analytics.

| Feature | Benefits |

|---|---|

| System Compatibility | Supports a wide range of industry standards like OPC, MQTT, ensuring seamless integration with existing systems. |

| Data Analytics | Advanced tools for real-time monitoring and control, crucial for making informed decisions in dynamic environments. |

| User Interface Consistency | Ensures a unified user experience across all devices, crucial for maintaining operational consistency and efficiency. |

| Modular Design | Offers scalability and the flexibility to add or modify functionalities as business requirements evolve. |

| Technical Support | Robust support structure with a large team of experts, ensuring minimal downtime and efficient troubleshooting. |

OneView® SCADA not only brings advanced tools for system compatibility and data analytics but also boosts operational visibility. It blends with older systems or adopts the latest IoT technologies. The adaptability and scalability it provides are crucial for today’s industries.

Choosing OneView® SCADA software ensures your investment is secure against future tech changes. Its non-proprietary, adaptable nature, combined with unlimited licensing and a modular structure, positions OneView® SCADA as the perfect choice for scalable growth and sustainability.

Selecting the right SCADA solution is imperative for your operational framework. OneView® SCADA equips your business with instantaneous data insights and unparalleled operational intelligence, enhancing decision-making and efficiency.

Conclusion

Our deep dive into SCADA systems shows their major role across industries. This spans from essential oil and gas to rising alternative energy fields. The evolution of SCADA from basic telemetry to complex networks boosting industrial efficiency showcases significant advancement. Presently, SCADA fuses sensors, RTUs, PLCs, and HMIs into unified systems. This offers operators exceptional oversight and data, improving decisions and operational efficiency.

In areas like transportation, healthcare, and manufacturing, SCADA meets various demands. It supports adherence to tough health and safety standards and the enactment of reliability-centered upkeep strategies. Via strategic automation, these systems enable bringing advanced tech into existing industry structures. This promotes comprehensive and preventative asset management plans. The crucial role of SCADA in keeping power grids stable and preempting equipment failures highlights their irreplaceable value in today’s industries.

The link between SCADA and Industry 4.0 grows clearer as we delve deeper into the digital age. With artificial intelligence and machine learning integration on the horizon, SCADA is set to elevate industrial processes. This move towards autonomous operation signals the future direction of strategic automation. SCADA’s adaptability and innovative applications are key to not just industrial productivity. They’re also vital for economic robustness and gaining a competitive advantage in the tough global arena.

FAQ

What Is SCADA?

SCADA means Supervisory Control and Data Acquisition. It’s essential in industrial automation for overseeing and managing equipment operations across many processes. By allowing remote management, SCADA systems enhance efficiency and cut costs via real-time data and automated control actions.

What are the core components of a SCADA system?

SCADA systems consist of sensors and inputs for data collection, PLCs or RTUs for data processing, and HMIs for operator interaction. Together, they enable supervisory control and data collection in industrial environments.

What role does supervisory control play in industrial automation?

Supervisory control is key in industrial automation for consistently overseeing and managing processes. It ensures operational efficiency, reliability, and safety by automating adjustments, reducing human error, and maintaining compliance.

How do SCADA systems streamline production processes?

By automating controls, SCADA systems enhance production reports and response times. They allow operators to adjust processes in real-time, using precise data. This boosts workflow efficiency and responsiveness.

How can data-driven decision making be enhanced with SCADA?

SCADA provides detailed data for informed decisions in real-time. Analyzing process variables, trends, and alarms helps optimize production and save energy. Strategic decisions based on this data drive operational excellence.

What is the impact of SCADA on reducing downtime and maintenance costs?

SCADA aids in lowering downtime and maintenance costs through predictive maintenance alerts. It lets operators fix issues before failures happen. This approach decreases outages, prolongs equipment life, and optimizes maintenance, saving costs.

How do connectivity and communication protocols affect SCADA networks?

Effective data exchange in SCADA networks hinges on connectivity and protocols like OPC UA and Modbus. They ensure secure, efficient communication, vital for industrial automation’s diverse needs.

What is the role of PLCs & RTUs in SCADA?

In SCADA, PLCs and RTUs are pivotal. They link sensors and actuators to the supervisory system. These components handle data gathering, local controls, and communication with the SCADA software for overarching control.

How does HMI SCADA facilitate interface and data visualization?

HMI in SCADA provides a graphical interface for operators to easily visualize and manage process data. It displays real-time and historical data, simplifying industrial operations management. This crucially improves operational understanding and response times.

What security challenges do SCADA networks face?

SCADA networks face security risks like cyber-attacks and unauthorized access, threatening operations and data integrity. Addressing these requires secure protocols, authentication, and vigilant monitoring to protect against threats.

How can robust SCADA security measures be implemented?

Strong SCADA security demands a mix of secure protocols, access controls, and regular audits. Constant system monitoring and staff security training are crucial for defending against new threats.

In what ways can SCADA integrate with other industrial systems?

SCADA’s integration with ERP, MES, and CMMS systems enhances operational efficiency. It ensures seamless data sharing and coordinated actions, leading to better planning and maintenance outcomes.

How has SCADA International impacted industrial automation?

SCADA International has greatly influenced industrial automation with its OneView® SCADA system. It provides comprehensive monitoring across renewable energy operations, streamlining complex tasks and advancing automation technology in various fields.

What should businesses consider when choosing SCADA software?

Choosing SCADA software involves assessing compatibility, communication support, interface usability, and analytics capabilities. Scalability for future growth is also key. Companies like SCADA International offer solutions that boost operational performance.

3 thoughts on “Save Time & Money: Discover How A SCADA System Works!”

Comments are closed.