Have we underestimated the transformative power of Distributed Control System in redefining industrial automation? The robust structures of PLC and DCS have underpinned process control for years. They’ve propelled us toward remarkable efficiency, productivity, and real-time control. Understanding how distributed control system work involves recognizing its components, such as computers, sensors, and controllers, spread throughout a factory or plant. This decentralized system allows for operational continuity during failures and distinguishes itself from centralized control systems, making it particularly effective in industrial applications. Yet, facing rapid changes, should we reimagine the future of automation technology?

As industrial automation leaders, we acknowledge the pivotal role of Distributed Control Systems in manufacturing’s future. Having a legacy that spans nearly half a century, DCS remains vital to process control. It ensures safety and boosts intelligence in production systems.

ABB sees Process Automation Systems becoming more adaptable, reliable, and secure. This evolution allows industries to thrive in a changing marketplace. However, traditional reluctance to change DCS architectures looms large. The industry now teeters on the brink of innovation. Supcon Technology’s Universal Control System (UCS) heralds a “cloud-network-end” architecture. This simplification propels efficiency to unprecedented levels.

Present-day DCS challenges revolve around poor interoperability and proprietary constraints. They make room for significant adaptations. Today’s Distributed Control System transcends simple refinements; it reimagines them. Integrating cloud technology, machine networking, and Ethernet APL, it dismantles data silos. It heralds a future dominated by minimally invasive architectures.

Key Takeaways

Distributed Control Systems are critical in enhancing the operational efficiency and real-time control of various industries.

ABB’s envisioned Process Automation Systems demonstrate the need for adaptable and secure distributed control solutions.

Challenges faced in traditional DCS platforms emphasize the demand for openness and improved interoperability.

Supcon’s UCS Nyx is a transformative DCS innovation, offering a simplified “cloud-network-end” structure for efficiency.

Decoupling of software and hardware in UCS architectures marks a significant evolution in DCS design principles.

Integration of Ethernet APL technology in modern DCS enhances communication efficiency and reduces transformation costs.

By understanding these developments, we can better envision how Distributed Control Systems will shape the future of industrial automation technology.

Historical Evolution of Industrial Automation

The journey of industrial automation chronicles ongoing progression and adaptability to market demands. This evolution has reshaped industry operations, underlining innovation’s crucial role in industrial automation.

From Relay-Logic to Programmable Logic Controllers (PLC)

The 1960s introduction of PLCs marked a significant departure from traditional relay control systems. Offering unmatched flexibility and reprogramming ease, these controllers established new norms. Systems like the Allen Bradley PLCs in the 1970s revolutionized the market. This phase set the stage for using sophisticated control systems like SCADA, enhancing industrial automation functionality.

The leap in programmable logic was fundamental, enabling precise control over operations through PID and motion controllers integrated into industrial workflows.

The Advent of Distributed Control Systems (DCS)

The historical development of process control systems paved the way for the move from central mainframes to minicomputers, enabling the rise of DCS. Honeywell’s TDC 2000 led this wave, altering perceptions and utilization of control systems industry-wide. The evolution to PC-based DCS alternatives made these functionalities more accessible, offering them affordably with less complexity. Today, DCS integration extends to various local levels, ensuring communication between the central control system and numerous distributed controls.

Innovation Beyond Technology: Adapting to Market Needs

The dynamic adaptation to market needs is evident in the ongoing advancement of control systems like DCS and PLC for complex automation. This includes integrating robotic process automation (RPA) to optimize operations and reduce delays. Innovations by companies such as Rosemount in sensor technology have broadened their industry impact, meeting specific automation needs. These advancements not only boost efficiency but also lead to significant cost reductions and competitive benefits worldwide.

To deep dive into how DCS can boost industrial automation, check out our detailed analysis here.

The strategic insertion of cutting-edge technologies like artificial intelligence and machine learning heralds a new innovation wave in this field. This shift is steering the sector towards more autonomous solutions, marking a new automation era.

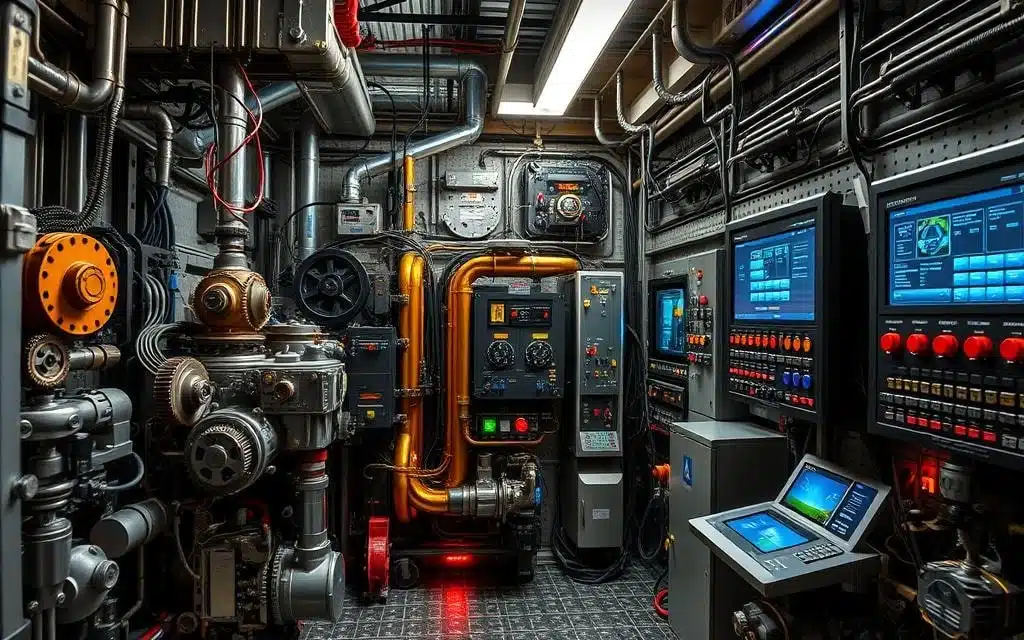

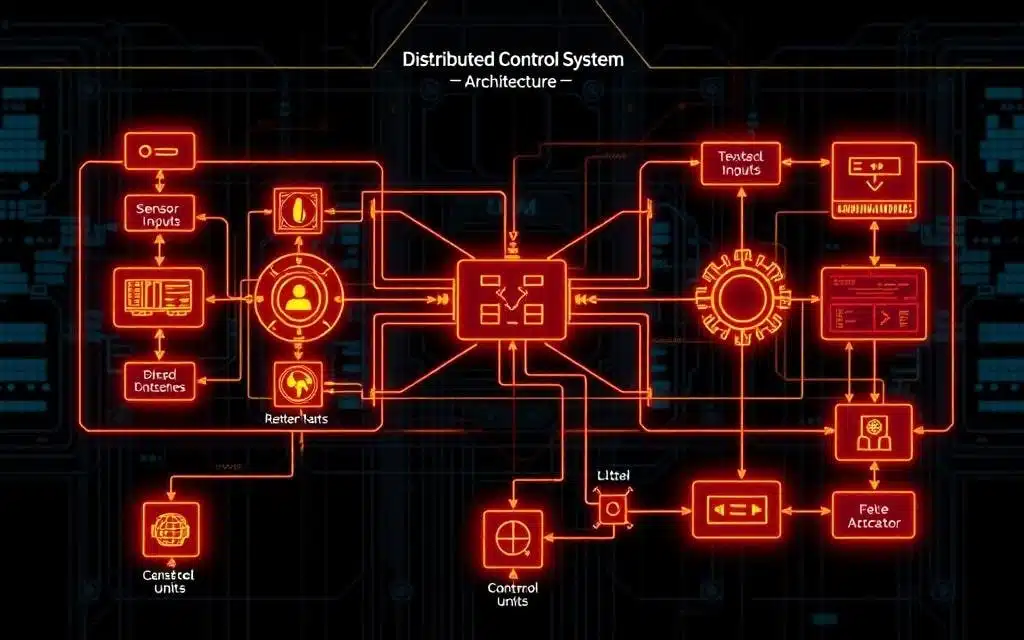

The Anatomy of a Distributed Control System

Grasping the DCS architecture is essential for boosting operational efficiency. It’s also key to seamless control system integration. A Distributed Control System (DCS) places control functions nearer to operations. The process control unit plays a crucial role in data collection and processing, ensuring operational continuity and reliability by managing inputs from sensors and smart devices for further analysis and output generation. This not only improves efficiency but facilitates real-time process control. It transforms real-time data into actionable insights.

Decentralizing Control for Operational Efficiency

Distributed control systems offer a major benefit by having multiple distributed controllers connected, spreading control tasks across several subsystems while keeping a centralized operation interface. This approach helps DCS lower latency and accelerate response times in crucial situations. Furthermore, decentralized systems increase reliability and toughness. These qualities are indispensable in scenarios where milliseconds can affect production quality.

Components & Connectivity Within Modern DCS Architectures

The modern DCS architecture features many layered components within industrial control systems. They function together to oversee and manage industrial processes. Key to its effectiveness is high-speed communication networks. These networks ensure fast information and command exchanges among system modules. This connectedness leads to advanced monitoring and control. It supports exceptional operational efficiency and sturdy real-time process control.

Let’s review the operational capabilities of a well-integrated DCS:

| Metric | Requirement |

|---|---|

| Resolution Time for Alarms | At least 1 ms |

| Cycle-Time for Closed Loop Controls | 0.2 – 0.5 seconds |

| Display of Mimic Diagram upon Request | 1 to 1.5 seconds |

| Alarm Display Time | 1 second |

| Confirmation of Operator Commands | 1 to 1.5 seconds |

This data highlights the importance of a well-engineered DCS. It must handle control system integration effectively. Boosting operational efficiency and ensuring peak functionality in tough industrial settings are critical.

Operational Advantages of DCS in Industrial Settings

The modern industrial landscape is complex, yet the adoption of Distributed Control Systems (DCS) vastly increases efficiency. Various process industries like chemical, pharmaceutical, and power generation see significant advances in operational efficiency and product quality through scalable control systems.

DCSs are vital for continuous production with minimal downtimes, especially in critical sectors such as oil and gas, and water treatment. Their architecture’s flexibility also means they can scale easily, accommodating growth or new technology seamlessly. DCS technology represents a significant leap towards realizing highly efficient, reliable, and scalable industrial ecosystems. DCSs are transforming various industries:

In the chemical industry, they streamline processes like mixing and separation. This boosts productivity while minimizing waste and energy use.

Pharmaceutical manufacturers depend on DCSs for maintaining high quality and adhering to global health standards.

The power generation sector achieves improved safety and efficiency with DCSs, vital for handling complex energy plant operations.

Additionally, combining DCS with technologies like SCADA and IIoT elevates its effectiveness. This fusion enables advanced, real-time monitoring and comprehensive data analytics, essential for today’s industrial demands.

| Industry | Key Advantages of DCS | Examples |

|---|---|---|

| Oil and Gas | Improved process efficiency and safety | Upstream production optimization |

| Water Treatment | Automated monitoring of treatment processes | Filtration and disinfection control |

| Manufacturing | Reduced production downtime | Automated control in automobile manufacturing |

| Electric Power | Safe and efficient operation | Control in nuclear and renewable energy plants |

DCS radically improves operations, preparing industries for future hurdles while promoting growth in the competitive global market. As DCS systems evolve, they push industries towards unparalleled operational precision and reliability.

Automation Technology Trends: DCS, PLC, SCADA, & Beyond

The industrial landscape is changing rapidly, as DCS, PLC, and SCADA systems evolve and merge. For anyone in automation, keeping up with these automation technology trends is essential.

Convergence of DCS & PLC Technologies

The merging of DCS and PLC technologies, including the role of the programmable logic controller, is not just a trend but a significant shift. It combines DCS’s reliability with PLC’s flexibility. By integrating the advantages of both, operations in various industries like manufacturing and energy become more efficient.

Enhancing Process Control with SCADA Integration

By integrating SCADA with DCS frameworks, industries gain more supervisory control and insight into their operations. This leads to smarter decisions and better efficiency.

Here’s a comparison of DCS, PLC, and SCADA systems’ traditional roles versus their new capabilities with SCADA integration:

| System | Traditional Functions | Integrated Capabilities |

|---|---|---|

| DCS | Centralized control, complex process management | Enhanced reliability, reduced downtime through redundancy |

| PLC | Discrete control, high-speed operations | Greater flexibility, adaptive to changes in process requirements |

| SCADA | Remote monitoring, broad area control | Real-time data acquisition, advanced analytics integration |

The merging of IT and operational tech through ICSS is making systems more cohesive. Adaptation of these automation technology trends not only enhances current operations but sets the stage for future innovations.

Distributed Control System & Real-Time Control Capabilities

In today’s advanced industrial sectors, Distributed Control Systems (DCS) are crucial. They provide the backbone for top-tier manufacturing by offering robust real-time control. Such systems enhance production speed and integrate complex adaptive systems. This integration is vital for staying ahead in fast-changing markets.

DCS enables industries to use real-time data for optimizing operations and increasing production speed. This improves consistency and quality. Meanwhile, DCS’s adaptability makes managing complex processes and complex adaptive systems easier. It ensures variables are continuously monitored and adjusted, optimizing production processes.

Advanced DCS technologies are essential where precision and reliability are key. They find use across various sectors. This includes pharmaceuticals, food processing, and chemical manufacturing. Their versatility and significance in industrial operations cannot be overstated.

Impact on Production Speed & Consistency

DCS systems boost production speed while maintaining quality. They provide real-time control for immediate adjustments. This reduces downtime and increases throughput. Such efficiency is particularly critical in sectors like pharmaceuticals. There, timing and consistency are crucial for market readiness and compliance.

Facilitating Complex Adaptive Systems in Manufacturing

The robust architecture of DCS simplifies integrating complex adaptive systems in manufacturing. This supports a dynamic environment. Machine learning and predictive analytics optimize performance and predict maintenance without human intervention. Therefore, DCS actively enhances operational frameworks, vital for the modern manufacturing scene.

| Feature | Benefit | Industry Application |

|---|---|---|

| Real-time monitoring and control | Increased operational efficiency and safety | Chemicals, oil refineries |

| Data-driven decision making | Enhanced quality and compliance | Pharmaceuticals, food processing |

| Adaptive system integration | Optimized process adjustments and maintenance prediction | Automotive manufacturing, energy management |

Incorporating DCS in industrial operations significantly boosts productivity through advanced real-time control. It also manages complex adaptive systems efficiently. These systems are not merely tools; they are strategic assets driving industry 4.0. They enable performance adjustments in real time, aligning with enterprise goals and market demands.

Industrial Internet of Things (IIoT) & the Role of DCS

The integration of the Industrial Internet of Things (IIoT) with distribution control systems (DCS) revolutionizes industrial automation. By combining M2M communication with data-driven tech, it elevates operational efficiency and predictive capability.

IIoT plays a critical role in modern industry, connecting equipment seamlessly. With AI integration in automation, it forms advanced networks. These networks not only communicate but also learn from every interaction, leading industries to unparalleled efficiencies.

Embracing M2M Communication in Automation

M2M communication is crucial within IIoT for connectivity and data exchange. It enables automated, real-time decisions, minimizing human oversight. DCS ensures uninterrupted data flow between devices, boosting system efficiency and reliability.

Optimizing with Predictive Maintenance & AI Integration

Predictive maintenance, powered by AI, is a leading IIoT application. It aims to minimize downtime and maintenance costs by anticipating failures. This proactive strategy improves equipment longevity and asset management. AI’s role in aggregating and analyzing data elevates DCS platforms, optimizing operations and predicting outcomes more accurately.

The continual fusion of IIoT and DCS across sectors enhances the potential for smarter industrial systems. This shift not only boosts efficiency but also drives sustainable advances in automation. It ensures industries remain competitive in the dynamic tech landscape.

Control System Integration: Challenges & Solutions

Technology evolves constantly, bringing challenges in control system integration to the forefront in industry. To stay competitive and effectively control industrial processes, integration of systems like DCS, SCADA, and PLC is critical. Achieving seamless system integration boosts reliability and efficiency significantly.

Effective integration taps into control engineering to ensure system compatibility. A thoughtful strategy is necessary to avoid issues like data redundancy. It involves careful planning and a detailed execution plan.

Overcoming the Barriers to Seamless Integration

The drive for quality and sustainability meets obstacles, including regulatory and technological complexity. Integrating systems in line with IEC 61850 standards promotes efficiency. It streamlines operations. However, issues such as legacy equipment compatibility present significant challenges.

Leveraging Control Engineering for System Compatibility

At the heart of effective integration lies expert application of control engineering. Utilizing platforms like EcoStruxure Foxboro DCS enhances industry resilience. Insights from Cross Company’s control engineering highlight the need for standard interfaces.

Adopting a phased integration strategy is key. This approach ensures a smooth process that meets business and regulatory needs. It addresses the critical challenges in control system integration efficiently.

The Role of Human-Machine Interface (HMI) in DCS

The integration of Human-Machine Interfaces (HMIs) within Distributed Control Systems (DCS) has revolutionized user interaction in the central control room of DCS. This revolution boosts the efficiency and safety of industrial operations significantly. HMIs enable a more intuitive interaction between operators and sophisticated control systems. They play a crucial role in modern automation settings.

Advancing User Interaction with Control Systems

Enhanced HMI design is vital for effective user interaction in DCS, with the central control room communicating essential data to operators. It offers operators a clearer and more immediate comprehension of system statuses and anomalies. This is especially important in industries like oil and gas, chemical processing, and power generation. Here, decisions need to be rapid and based on accurate information. We strive to make these interfaces not only functional but also user-friendly. Our goal is to reduce complexity and maximize operational efficiency.

Enhancing Safety & Response Times Through Improved HMI

The development of HMIs has notably uplifted safety in automation. It achieves this through designs that emphasize clear visual cues and easy navigation. Such focus is critical in minimizing response times during critical situations. This optimization enhances the overall safety and productivity of the system. Response time optimization is not merely about speed. It’s also about how effectively an operator can respond to system changes. This ensures safety and continuity in operations.

| Feature | HMI | DCS |

|---|---|---|

| User Interaction | Flexible, customizable interface | Standardized, robust systems |

| Safety | Quick response to company-specific needs | Highly reliable and secure |

| Cost Effectiveness | More hardware dependent | Higher initial cost but long-term savings |

To further understand the nuances of HMI and DCS functionalities within industry settings, visit this resource. It offers detailed insights into integrated control and safety systems. As industrial automation continues to evolve, the significance of HMIs in enhancing both automation safety and response time efficiency is undeniable.

Future-Pro: Where DCS Is Paving the Way for Advanced Manufacturing

The landscape of advanced manufacturing is transforming significantly. This change is mainly due to advancements in DCS development. As industries grow, merging distributed control systems with technologies like IoT and cloud computing becomes essential. This fusion is key for driving digital transformations in automation, boosting flexibility and intelligence in manufacturing processes.

The pursuit of sustainability highlights DCS’s vital role. Modern DCS frameworks enhance sustainable manufacturing by reducing waste and optimizing resource usage. This meets today’s environmental demands, blending good ethics with smart business tactics. The combination of DCS and sustainability in manufacturing fosters eco-friendly production environments, contributing to a healthier planet.

| Technology | Impact on Manufacturing |

|---|---|

| Industrial Robots | Increases productivity by 30% |

| Flexible Automation Systems | Adapts to production volume changes by up to 40% |

| SCADA Systems | Improves operational efficiency by 15% |

| DCS Systems | Reduces downtime by 10% |

The future of DCS focuses on enhancing and revolutionizing manufacturing capabilities. By promoting digital transformations in automation, DCS development seeks to improve automation’s adaptability and reliability. This evolution aims at better efficiency, sustainability, and operational excellence in the manufacturing sector.

Looking ahead, blending AI and real-time data analysis with DCS will empower manufacturers even more. These technologies enhance predictive maintenance, which has been shown to increase accuracy by 20%. This minimizes surprises in downtime and cuts operational costs. This approach in advanced manufacturing goes beyond avoiding failures. It’s about fostering proactive strategies that boost productivity and sustainability.

Conclusion

In the realm of industrial automation, leaders like us have witnessed significant progress with Distributed Control Systems (DCS) adoption. Honeywell’s 1969 innovation marked the start of this transformative journey. It has impacted various fields such as chemical plants, refineries, and water management systems. DCS technologies bring improved reliability, security, scalability, and lower operating costs, key for competitive manufacturing.

Our experience with DCS highlights that, despite the initial expense, the benefits are substantial in the long run. Organizations utilizing DCS have experienced up to a 20% increase in efficiency and 30% reduction in downtime. This boost in performance and decrease in failures demonstrate DCS’s strategic value in achieving operational excellence. However, it’s crucial to have specialized knowledge for effective DCS configuration and upkeep, ensuring ongoing success in automation.

The field of industrial automation is ever evolving, with DCS adoption growing by 15% annually. DCS systems stand out due to their flexibility and efficiency, connecting field devices with supervisory controls via advanced protocols, including industrial Ethernet. Those interested in learning more will find our guide on Distributed Control Systems invaluable. Collaborative efforts, like GE Renewable Energy’s partnership with Toshiba Energy Systems, highlight how DCS is revolutionizing automation, helping industries navigate the 21st century’s challenges and opening up new growth paths in global markets.

FAQ

What is a Distributed Control System (DCS)?

A Distributed Control System (DCS) is a kind of automated control system that places control elements near the process operation. Each component within the system communicates over a network. DCS systems manage complex, geographically spread processes, mainly in industrial settings. They provide real-time control and enhance process dependability.

How has industrial automation evolved with the advent of PLC and DCS?

Industrial automation has seen significant evolution from early reliance on relay-logic to embracing Programmable Logic Controllers (PLC) and Distributed Control Systems (DCS). Introduced by Dick Morley, PLCs replaced relay-logic with digital systems, offering enhanced flexibility and control. Honeywell’s launch of the TDC 2000 made DCS a game-changer by decentralizing control, thereby boosting efficiency and reliability across numerous sectors.

What technological trends are affecting DCS and PLC systems?

The blending of DCS and PLC technologies is a key trend, merging their strengths to optimize process and system cooperation. Integration with SCADA systems is improving real-time data insights and visualization. The inclusion of IoT and Artificial Intelligence is revolutionizing operations through predictive maintenance and advanced analytical capabilities.

How does a Distributed Control System enhance industrial operational efficiency?

By decentralizing control, DCS improves operational efficiency, leading to faster response times and proper process adjustments. This results in superior product quality, lesser downtime, and increased productivity. It enables operators to focus on strategic initiatives while facilitating real-time process optimization.

What are the components and connectivity features of modern DCS architectures?

Modern DCS architectures consist of autonomous modules like controllers, input/output devices, and networks. They utilize high-speed protocols for real-time data exchange and responsiveness. These systems are interconnected with SCADA for improved visualizations, HMIs for user interaction, and IIoT devices for data-driven decisions.

How does DCS contribute to production speed and consistency in manufacturing?

DCS boosts production speed and consistency by enabling real-time control and ongoing process oversight. Instantaneous adjustments help avoid delays and maintain consistent quality standards. By managing adaptive systems within manufacturing, DCS dynamically responds to variances, ensuring steady production outcomes.

What is the role of DCS in the integration of IIoT in industrial automation?

DCS plays a key role in integrating IIoT, acting as the operational core for M2M communication, data analysis, and intelligent performance. It processes data from IIoT devices, facilitating predictive maintenance. DCS also leverages AI to improve production processes through informed decision-making.

What challenges are associated with control system integration in industrial settings?

Control system integration involves navigating compatibility problems among different technologies, securing efficient data communication, and adapting to technological advancements. Control engineering is pivotal in crafting strategic solutions that ensure smooth interconnectivity and standard interface across various systems.

How does Human-Machine Interface (HMI) enhance the performance of DCS?

HMI advances DCS performance by streamlining interaction between operators and control systems. It provides an intuitive interface, clear process visualizations, and easy controls. This allows operators to quickly address system changes and issues, maintaining awareness and safety through timely updates and alerts.

In what ways is DCS driving future advancements in advanced manufacturing?

DCS leads advancements in manufacturing by facilitating the adoption of digital innovations like IoT, machine learning, and cloud computing. These technologies make manufacturing operations more adaptive, responsive, and smart. They are crucial for addressing new challenges in sustainability, electrification, and digitization in today’s manufacturing sector.

4 thoughts on “Distributed Control System: Future of Industrial Automation”

Comments are closed.