Digital transformation in manufacturing is vital for success in today’s fast-changing industry. Industry 4.0 is gaining traction, pushing manufacturers to embrace digitalization. Ignoring this trend could leave companies trailing behind their rivals.

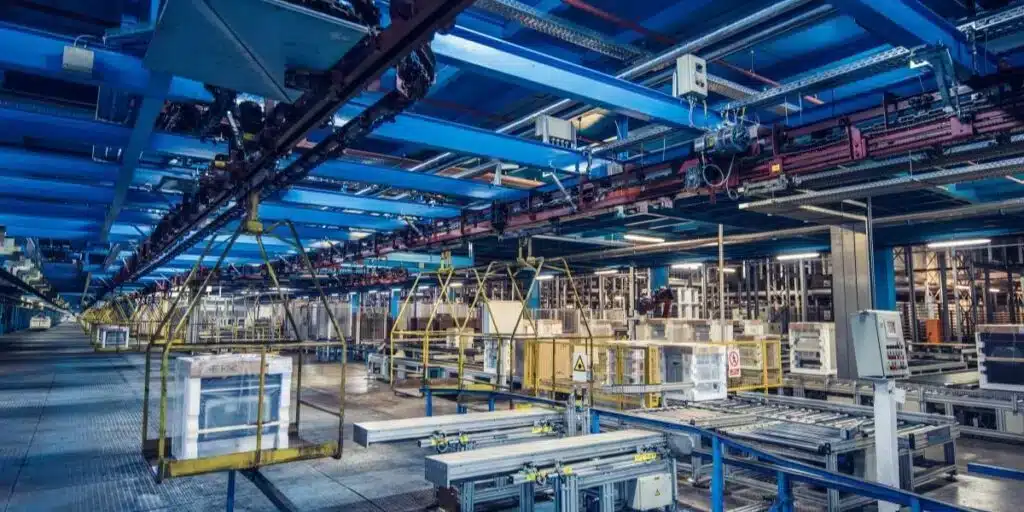

Smart factories, powered by automation and IoT, are changing production methods. Digital transformation unlocks new levels of efficiency, quality, and sustainability. Our recent report shows 45% of respondents see quality improvement as the main driver for digital transformation.

Digital transformation offers benefits beyond better quality. Advanced tech like IoT sensors and AI optimize production scheduling and inventory planning. These digital solutions also help solve problems faster, cutting costs and boosting efficiency.

The manufacturing industry faces a growing skills gap. By 2030, there could be 2.1 million unfilled skilled jobs. Digital tools can help bridge this gap.

These technologies automate repetitive tasks and provide workers with real-time data. This empowers employees and helps them make better decisions on the job.

Key Takeaways

Digital transformation is crucial for manufacturers to remain competitive in the Industry 4.0 era.

Improving quality and sustainability are key drivers for accelerating digital transformation.

Advanced technologies like IoT, AI, and machine learning optimize production processes and reduce costs.

Digital tools can help address the growing skills gap in the manufacturing workforce.

Embracing digital transformation is essential for manufacturers to unlock new levels of efficiency, quality, and sustainability.

Understanding Digital Transformation in Manufacturing

Digital transformation in manufacturing integrates advanced technologies into production processes. Understanding the digital transformation process is crucial for manufacturers aiming to keep pace with industry changes. It enhances product development, inventory management, and customer experience. Global spending on Industry 4.0 technologies is expected to reach $310 billion by 2023.

AI in manufacturing, machine learning, and supply chain digitization drive this transformation. These technologies optimize operations and improve efficiency across the manufacturing sector.

Definition of Digital Transformation

Manufacturing’s digital transformation adopts AI, IoT devices, cloud computing, and machine learning. These technologies optimize operations and streamline processes. As a result, manufacturers can improve efficiency and deliver better products to customers.

Importance in Today’s Economy

Geopolitical changes, productivity shifts, and evolving customer expectations drive digital transformation. Digital transformation efforts are essential for manufacturers to effectively manage data and overcome challenges associated with siloed information. Sustainability requirements also play a crucial role. Manufacturers embracing this change can reap numerous benefits.

These advantages include increased productivity, improved product quality, and enhanced customer satisfaction. Additionally, they can reduce costs, increase agility, and improve sustainability.

Increased productivity

Improved product quality

Enhanced customer satisfaction

Reduced costs and waste

Greater agility and responsiveness

Improved sustainability

Core Technologies Driving Change

Several key technologies are propelling digital transformation in manufacturing. A well-defined digital transformation strategy is essential for aligning technology initiatives with business goals and enhancing operational efficiency:

Technology | Application | Projected Growth |

|---|---|---|

Monitor equipment health for predictive maintenance and quality | 23% annual growth | |

Machine learning algorithms | Analyze data to improve predictive models and optimize processes | – |

Cloud-based architectures | Provide real-time visibility into the supply chain for proactive inventory management | – |

Computer-aided design (CAD) and product life-cycle management (PLM) | Accelerate product development | – |

Augmented Reality (AR) | Assist in training and maintenance | 54% increase in adoption over the next two years |

Training programs focusing on data analytics and IoT technologies have shown to increase operational efficiency by up to 30% in manufacturing plants.

Manufacturers face challenges when adopting digital transformation. These include integrating new technologies with legacy systems and ensuring cybersecurity. Creating a culture that embraces change and data-driven decision-making is also crucial.

Investing in the right technologies is key for manufacturers. Training their workforce is equally important. These steps will position them for success in the digital age.

The Benefits of Digital Transformation

Digital transformation in manufacturing companies offers many benefits. It boosts efficiency, productivity, and data analytics. It also improves supply chain management. McKinsey reports it can increase output by 10-30% and reduce machine downtime by 50%.

Increased Efficiency and Productivity

Digital transformation in manufacturing greatly improves efficiency and productivity. Automation in the manufacturing process cuts time for repetitive tasks, freeing up resources for other activities. Tesla’s Shanghai Gigafactory is 95% automated, producing a million cars yearly.

Real-time data analytics optimize workflows by spotting issues quickly. Machine monitoring provides live data on utilization, improving resource planning. Manufacturing Execution Systems boost efficiency and offer complete product traceability.

Enhanced Data Analytics Capabilities

Digital transformation gives manufacturers real-time visibility across all operations. A safe and efficient manufacturing environment is crucial for leveraging these advancements. Sensors collect live data for better decision-making in processes and inventory. Cloud platforms offer scalable, real-time insights for smarter choices.

AI and machine learning help track environmental impact and optimize energy use. Digital twins enhance efficiency and flexibility in manufacturing processes. Rolls Royce uses digital twins to predict aircraft engine maintenance needs.

Improved Supply Chain Management

Digital tech builds supply chain resilience through data-driven insights. It helps plan for future challenges. Cloud technology enables real-time inventory visibility and cross-team collaboration.

AI automates decision-making and predicts demand patterns in inventory management. 3D printing reduces waste and streamlines supply chains. Boeing 3D prints Apache helicopter rotor systems, cutting lead times.

Technology | Benefit | Example |

|---|---|---|

Automation | Increased efficiency and productivity | Tesla’s Gigafactory in Shanghai |

AI and Machine Learning | Predictive maintenance, quality control, demand forecasting | BMW’s real-time interaction between vehicles and production system |

Simulating performance, predicting maintenance needs | Rolls Royce’s digital twins of aircraft engines | |

Additive Manufacturing (3D Printing) | Reduced waste, streamlined supply chains, faster prototyping | Boeing’s 3D printed main rotor system for Apache helicopters |

Industry 4.0 technologies are changing IoT in manufacturing. IoT, AI, and augmented reality boost efficiency and improve data analysis. They also enhance supply chain management. Embracing digital transformation helps manufacturers succeed in today’s global market.

Key Technologies Driving Digital Transformation

Manufacturing is changing fast, thanks to digital transformation. New tech is making factories smarter and more efficient. Let’s look at the main technologies behind this change.

Internet of Things (IoT)

Internet of Things (IoT) is key to manufacturing’s digital shift. Smart devices collect real-time data from the factory floor. This data helps improve processes and machine performance.

IoT adoption in manufacturing is growing fast. Most leaders see it as crucial for success. Companies using IoT can cut costs and reduce downtime significantly.

Artificial Intelligence & Machine Learning

AI and ML are reshaping manufacturing. They help with scheduling, maintenance, and process optimization. These tools automate tasks and predict equipment failures.

AI and ML boost production and improve efficiency. They increase output, factory use, and worker productivity. Most workers believe automation helps them work better and make smarter choices.

Cloud Computing

Cloud tech opens new doors for manufacturers. It offers scalable IT and cost savings. Cloud platforms provide tools for analytics and teamwork.

Cloud computing enables remote monitoring and real-time analysis. It helps teams work together smoothly. Cloud solutions adapt easily to market changes and support other digital tech.

Technology | Key Benefits |

|---|---|

Real-time data collection, remote monitoring, improved efficiency | |

Artificial Intelligence and Machine Learning | Automation, predictive maintenance, optimization of operations |

Cloud Computing | Scalable IT infrastructure, cost reduction, advanced analytics |

IoT, AI, ML, and cloud tech form the base for future smart factories. These tools help manufacturers become more efficient and competitive in the digital world.

Case Studies: Successful Transformations

Digital transformation drives success in today’s fast-changing manufacturing world. Industry leaders use cutting-edge tech to improve operations and stay competitive. Let’s explore how some big companies have transformed digitally.

General Electric’s Digital Strategy

GE leads digital transformation in manufacturing. They use machine learning and predictive maintenance to boost efficiency and reduce downtime. GE’s digital supply chain improves supplier teamwork and market responsiveness.

Siemens’ Smart Manufacturing Initiative

Siemens revolutionizes operations with smart manufacturing. IoT and AI help optimize production, cut waste, and enhance product quality. Their digital twin tech speeds up design testing and lowers costs.

Bosch’s Industry 4.0 Implementation

Bosch pioneers Industry 4.0 principles in manufacturing. They invest in machine learning, predictive maintenance, and digital supply chains. This creates a flexible manufacturing system.

Bosch’s digital efforts have paid off. They’ve cut stocks by 30% with real-time tracking. Predictive maintenance has also boosted productivity by reducing downtime.

A 30% reduction in stocks with real-time visualization

Improved productivity by using predictive maintenance to reduce downtime

Other success stories include:

Company | Digital Transformation Impact |

|---|---|

Toyota | 50% reduction in production preparation lead time, 20% increase in productivity |

Airbus | Reduced rework during manufacturing by up to 20%, accelerated production |

Fortune 200 manufacturing company (using aiOla) | 60% reduction in incident resolution time, 4 fewer safety issues per shift |

These cases show how digital tech transforms manufacturing. Smart investments in tools and strategies boost efficiency and innovation. This positions companies for long-term success in a tough market.

Challenges in Implementing Digital Transformation

Digital transformation in manufacturing offers many benefits but faces several challenges. These obstacles can hinder successful adoption of digital technologies. This can lead to delayed progress and suboptimal results.

Resistance to Change

Manufacturers often face employee resistance to change. Digital transformation requires a significant shift in organizational culture. A recent survey found 42% of manufacturing leaders haven’t started their digital transformation journey.

Skills Gap in the Workforce

The digital skills gap is a major hurdle in implementing digital transformation. Employees need training to understand and use new technologies effectively. Many manufacturers struggle to provide adequate training and support.

Personalized learning paths and continuous support are vital for employee engagement. These methods enhance retention during the transformation process.

Integration with Legacy Systems

Integrating digital technologies with existing legacy systems is challenging for manufacturers. Understanding traditional manufacturing processes is crucial as companies undergo digital transformation. Many facilities use a mix of old and new technologies. This makes seamless integration a complex task.

Choosing adaptable technologies is essential to avoid early obsolescence. These technologies should evolve with changing industry needs to ensure a smooth transition.

The benefits of digital transformation outweigh the difficulties. Manufacturers can overcome obstacles by embracing change and investing in employee training. Selecting flexible technologies helps unlock the full potential of digital transformation.

Implementing solutions like augmented reality can help bridge the skills gap. These tools can improve efficiency and drive innovation in the manufacturing industry.

The Role of Leadership in Transformation

Leaders drive successful digital transformations in manufacturing. They guide companies through Industry 4.0, smart factories, and automation changes. Industry 4.0 is reshaping the manufacturing landscape rapidly.

By 2023, 93% of organizations had adopted or planned digital-first strategies. This highlights the need for strong leadership in digital transformation. CEOs, CDOs, and CTOs align these strategies with long-term goals.

They ensure the organization stays competitive in our digital world. Their role is crucial in setting clear visions for these initiatives.

Vision & Strategy Development

Digital transformation leaders in manufacturing must develop comprehensive strategies. This involves assessing current capabilities and finding areas to improve. They set clear, measurable goals for the transformation initiative.

Leaders allocate resources for technology, training, and change management. They also create plans to handle potential risks.

Fostering a Digital Culture

Building an innovative culture is key for adopting new technologies and processes. Effective communication from leaders builds trust among employees. This ensures a smooth transition to a digital-first approach.

“Projects with effective change management were seven times more likely to succeed than those with poor change management.” – Prosci research

Continuous Learning and Adaptation

Leaders must prioritize learning to stay ahead in the evolving manufacturing industry. This involves staying tech-savvy and making data-driven decisions. Being agile helps respond quickly to changes.

Initiative | Importance |

|---|---|

Leveraging technology savviness | Ensures informed decisions regarding technology adoption align with strategic goals |

Making data-driven decisions | Reduces reliance on instincts and promotes agility in decision-making |

Being agile and adaptable | Ensures rapid responses to internal and external triggers, maintaining competitiveness |

These leadership practices help manufacturing organizations navigate digital transformation challenges. They position companies for success in the era of Industry 4.0. Smart factories and automation are key parts of this new landscape.

Best Practices for a Smooth Transition

Manufacturers must assess their current capabilities to ensure a smooth digital transformation. They should identify areas where digital tech can make the biggest impact. This involves evaluating infrastructure, workforce skills, and operational processes.

Readiness for IoT, AI, and machine learning in manufacturing is crucial. Setting clear goals is essential for successful digital transformation. Manufacturers should align objectives with their overall business strategy.

Prioritizing initiatives that deliver measurable results is key. This may include improving efficiency, reducing costs, or enhancing product quality. Creating new revenue streams through innovative offerings is another possibility.

Invest in Training and Development

Bridging the skills gap is critical for preparing the workforce for the digital era. Employees need new skills to operate advanced technologies effectively. Ongoing training and support foster a culture of continuous learning and adaptation.

“Digital transformation is not just about technology; it’s about people. Empowering employees with the right skills and tools is key to driving innovation and success in the digital age.”

Few manufacturers have fully transitioned to Industry 4.0 due to various challenges. Legacy equipment, talent gaps, and budget constraints are common obstacles. Companies should adopt a phased approach to overcome these issues.

Starting with pilot projects and scaling up successful initiatives is recommended. Focusing on business outcomes during digital transformation can lead to maximum ROI. This approach ensures efficient operations in manufacturing industries.

The Future of Manufacturing: Trends and Predictions

Manufacturing is on the brink of major change. New digital technologies are reshaping the industry. These tools will boost growth, efficiency, and customer satisfaction.

Autonomous systems are gaining traction in manufacturing. By 2025, 80% of large businesses will invest in advanced workforce management software. This move aims to streamline production and cut costs.

Autonomous Manufacturing

Smart factories are changing how products are made. AI and machine learning enable minimal human involvement. A study shows 93% of manufacturers see AI as key to growth.

AI deployments in manufacturing focus on smart production. This tech accounts for 51% of AI use in the industry. It’s driving innovation and boosting efficiency.

Predictive maintenance is a major benefit of autonomous manufacturing. Sensors and data help prevent equipment failures. This approach cuts costs and extends machinery lifespan.

Sustainability and Green Technologies

Manufacturers are focusing more on sustainability. Consumer demand is driving this shift. By 2027, 30% of large global firms will prioritize software sustainability.

Cloud migration is one way to boost sustainability. Accenture’s research shows it could equal taking 22 million cars off the road. This move offers significant environmental benefits.

The Rise of Customization and Personalization

Customization is reshaping manufacturing’s future. Customers want unique, tailored products. Augmented reality and 3D printing help create personalized experiences.

“On-demand customization is a game-changer for manufacturers. It helps them stand out and build stronger customer relationships.”

Manufacturers are investing in supply chain digitization. This helps them respond quickly to changing customer needs. It also reduces lead times for custom products.

The manufacturing industry is evolving rapidly. Embracing new tech and trends will be key to success. Autonomous systems, sustainability, and customization are shaping the future.

Measuring the Success of Digital Transformation

Tracking progress is vital for manufacturers undergoing digital transformation. Clear goals and key performance indicators (KPIs) help ensure success. This approach guides companies towards building smart factories and embracing Industry 4.0.

Recent studies show 90% of businesses are transforming digitally. Notably, 56% of US companies report exceeding expectations. Manufacturers can achieve similar success by focusing on customer satisfaction, operational efficiency, and employee engagement.

Key Performance Indicators (KPIs)

Tracking the right KPIs is crucial for measuring digital transformation success. Important metrics include:

Customer satisfaction scores and digital engagement levels

Process cycle times and automation rates

New revenue streams and market share growth

Employee productivity and digital skills advancement

Customer Satisfaction Metrics

Digital analytics and business intelligence (BI) platforms offer insights into customer behavior. These tools help analyze website and app interactions. Manufacturers can understand how well their digital strategy resonates with target audiences.

Direct customer feedback through integrated tools provides opportunities for continuous improvement. This approach ensures customer needs are met effectively.

Employee Engagement Levels

Measuring employee engagement is essential for successful digital transformation. Key metrics include productivity, digital skills advancement, and content platform interaction. These indicators show how well employees adapt to new technologies and processes.

Custom dashboards enable real-time monitoring of KPIs. This allows manufacturers to make data-driven decisions and foster continuous improvement.

Companies like Boa Vista, AeroSud, and Algar Telecom have successfully transformed digitally. They use data-driven approaches and centralized dashboards. These manufacturers have improved delivery cycles, response rates, and customer experience.

The Importance of Cybersecurity

Digital transformation in manufacturing has made cybersecurity crucial. Automation, IoT, and AI have expanded the potential for cyber threats. Over 60% of manufacturers expect cyberattacks this year.

Cybersecurity protects data and ensures business continuity. A successful attack can disrupt production and cause financial losses. Industry leaders now prioritize investing in robust cybersecurity measures.

Protecting Sensitive Data

Cybersecurity in manufacturing aims to protect sensitive data. This includes intellectual property, customer info, and financial records. Firewalls, encryption, and multi-factor authentication are now standard practices.

Compliance with standards like SOC 2 Type 2 and NIST 800-171 is crucial. GDPR and CCPA also play a role. Regular risk assessments and internal audits are essential for proactive cybersecurity.

Integrating Security into Digital Tools

Manufacturers must integrate security into their digital tools. This involves securing devices, implementing network segmentation, and updating systems regularly. Gartner identifies key trends in manufacturing cybersecurity.

These trends include generative AI, cybersecurity metrics, and human-centric security practices. Third-party risk management and identity access management are also important. Incorporating these trends creates a more secure environment.

Best Practices for Cyber Safety

Manufacturers must adopt best practices for strong cybersecurity. These include regular employee training and strict access controls. Monitoring systems and developing incident response plans are also crucial.

Conducting regular employee training on cybersecurity awareness

Implementing strict access controls and permissions

Monitoring systems for suspicious activity

Developing incident response plans

Collaborating with trusted technology partners to ensure the latest security measures are in place

Best Practice | Importance |

|---|---|

Employee Training | Educates staff on identifying and reporting potential threats |

Access Controls | Ensures that only authorized personnel can access sensitive data and systems |

System Monitoring | Detects and responds to suspicious activity in real-time |

Incident Response Plans | Minimizes the impact of a successful cyberattack and ensures rapid recovery |

Technology Partnerships | Leverages expertise and resources to implement the latest security measures |

Prioritizing cybersecurity gives manufacturers a competitive edge. It enables confident innovation and product launches. A strong strategy ensures secure and resilient infrastructure for future growth.

Collaborative Solutions in Digital Transformation

Collaboration unlocks the potential of emerging technologies in digital transformation. Manufacturers can streamline processes by fostering cross-departmental teamwork and partnering with tech experts. Digital collaboration tools enable seamless teamwork, regardless of location or expertise.

Digital twins are powerful collaborative tools. These virtual replicas simulate scenarios and optimize operations. They enable predictive maintenance, reducing downtime and improving equipment effectiveness.

Digital twins also facilitate supply chain digitization. This allows real-time monitoring and optimization of the entire value chain.

Cross-Departmental Collaboration

Breaking down silos is crucial for successful digital transformation. When teams collaborate, innovation thrives, and performance improves. However, resistance to change and conflicting objectives can hinder progress.

Companies must foster a culture of collaboration. Aligning teams towards common goals is essential for overcoming obstacles.

Engaging with Technology Partners

Partnering with tech providers accelerates digital transformation. These partnerships offer specialized expertise, cutting-edge tools, and best practices. When choosing collaboration software, consider real-time file sharing and multi-device support.

Cloud-based solutions and integration capabilities are also important factors. Leveraging partners’ knowledge helps manufacturers stay ahead of the competition.

Using Digital Twins for Simulation

Digital twins revolutionize manufacturing by creating virtual representations of physical assets. This technology enables scenario simulation and process optimization. Machine learning in production environments enables predictive maintenance.

Digital twins improve equipment effectiveness and reduce downtime. They also allow real-time monitoring and optimization of the entire supply chain.

Embracing collaborative solutions is not just a nice-to-have; it’s a necessity for survival in the digital age. Companies prioritizing collaboration experience lower costs and improved productivity. This leads to increased ROI and customer satisfaction.

A lack of collaboration can cause inefficiencies and lower sales. This poses a threat to an organization’s long-term success.

Conclusion: Embracing Change in Manufacturing

Manufacturers must adapt to stay competitive in today’s fast-paced business world. Digital transformation is crucial for success in Industry 4.0. Advanced technologies can boost efficiency, productivity, and innovation in manufacturing.

By adopting augmented reality, artificial intelligence, and IoT, companies can reach new heights. These tools unlock potential for growth and improvement. Industry 4.0 offers exciting opportunities for forward-thinking manufacturers.

The Need for Continuous Innovation

Innovation is vital for manufacturing success. Companies must actively explore and implement new solutions. Digital transformation can streamline processes and enhance product quality.

IoT devices enable real-time data monitoring in manufacturing. This leads to improved efficiency, less downtime, and increased productivity. Embracing these technologies is key to staying competitive.

Benefits of Staying Ahead of Competitors

Digital transformation gives manufacturers a competitive edge. It allows quick responses to market changes and personalized offerings. This results in improved customer satisfaction and stronger market position.

Studies show digital initiatives boost efficiency in manufacturing. A 2021 IBM study found 67% of manufacturers are rapidly adopting digital technologies post-pandemic.

A Call to Action for Manufacturers

It’s time for bold steps towards digital transformation. Investing in technology and fostering innovation are crucial. Upskilling the workforce is also essential for long-term success.

Challenges like resistance to change and skills gaps exist. However, the benefits outweigh the risks. Manufacturers must seize Industry 4.0 opportunities to thrive.

By embracing change, companies can shape a prosperous future. The time to act is now. Don’t let your organization fall behind in this digital revolution.

FAQ

What is digital transformation in manufacturing?

Digital transformation in manufacturing integrates new technologies into various aspects of production. It uses AI, IoT devices, cloud computing, and machine learning to improve operations. These tools enhance product development, inventory management, and customer experience.

Why is digital transformation important for manufacturers?

Digital transformation keeps manufacturers competitive in today’s fast-paced market. It can increase throughput by 10% to 30% and improve quality costs by 10% to 20%. Machine downtime can be reduced by up to 50%. This change gives real-time visibility on all operations. It covers the production floor, supply chain, and more.

What are the key technologies driving digital transformation in manufacturing?

IoT, AI, machine learning, and cloud computing are driving digital transformation in manufacturing. These technologies collect real-time data and optimize processes. They also predict maintenance needs and create digital twins for simulation.

What are some real-life examples of successful digital transformations in manufacturing?

General Electric, Siemens, and Bosch have successful digital transformations in manufacturing. They use IoT, AI, and cloud computing to create business value. These changes reduce costs, enhance quality, and increase flexibility. They also improve sustainability and boost employee productivity.

What challenges do manufacturers face when implementing digital transformation?

Manufacturers face resistance to change, skills gaps, and integration with old systems. Training workers is a big challenge. New solutions are useless if workers can’t use them effectively.

How can manufacturers ensure a smooth transition to digital manufacturing?

For a smooth transition, assess current capabilities and set clear goals. Invest in training and development. Start with one area of innovation, like cloud computing or AI. Find a strategic partner to help choose the right solutions. They should understand your specific challenges and needs.

What trends will shape the future of manufacturing?

Future manufacturing trends include autonomous production, green technologies, and personalized products. Digital transformation can reduce CO2 emissions and water use by about 15%. This is mainly due to sustainability software and digital lean strategies.

How can manufacturers measure the success of their digital transformation initiatives?

Track key performance indicators, customer satisfaction, and employee engagement. Digital SQCDP boards help managers assess bottlenecks and plan next steps. Color-coded visuals make it easy to spot issues quickly.

Why is cybersecurity critical for manufacturers undergoing digital transformation?

As manufacturers rely more on digital tech, cybersecurity becomes crucial. Protect sensitive data and integrate security into digital tools. Stay informed about the latest threats and vulnerabilities.

How can collaborative solutions support digital transformation in manufacturing?

Collaborative solutions are key to successful digital transformation. Cross-department teamwork aligns all stakeholders towards common goals. Tech partners provide specialized expertise and resources. Digital twins help simulate production with different settings. This helps find the best machine setups and workforce organization.

2 thoughts on “Why Digital Transformation in Manufacturing Matters Now?!”

Comments are closed.