Do we ever consider the silent powerhouses behind our daily lives like wireless scada system? Think about the unseen mechanisms that power our homes, oversee water supplies, or lead the vast manufacturing sectors. At the core of such management lies wireless SCADA systems—key in industrial automation. These systems turn real-time data acquisition into the backbone of effective operations, where SCADA security is crucial.

This guide uncovers the complexity and hurdles of wireless SCADA systems, their growth, and their role in evolving industrial automation. We will look at how remote terminal units (RTUs) link to the control center through IR1800. We’ll also cover the critical need for secure IPSec tunnels, especially with rising cyber threats. Join us to understand these powerful systems better.

Learn about SCADA’s essential role in various industries and its impact on operations through our detailed resource on wireless SCADA systems. Discover advances in technology that boost the capabilities of industrial networks and protect them from cyber risks.

Key Takeaways

The significance of employing wireless SCADA systems in various industrial sectors.

Understanding the role of RTUs within the SCADA network and the implications for industrial automation.

Exploration of the IR1800’s critical functions, such as protocol translations IEC 60870 and DNP3, ensuring uninterrupted data flow.

A closer look at SCADA security and the imperativeness of safeguarding data traversing public infrastructures.

Anticipating future challenges and opportunities within the realm of real-time data acquisition and SCADA system security.

The Evolution & Importance of Wireless SCADA Systems

In the realm of industrial automation, the evolution from wired to wireless infrastructure in SCADA systems is pivotal. It signifies technological progress and a shift in industry operations and remote resource management. This transformation is foundational, marking a new era in how industries function.

The 1960s saw the debut of SCADA systems, heralding enhanced efficiency in various sectors. Now, these systems’ fusion with IoT technologies is essential in modern industrial automation, not just a fleeting trend.

Understanding SCADA in the Modern Industrial Landscape

SCADA systems now exceed traditional roles, central to remote monitoring that’s dynamic and can manage intricate processes. By 2019, SCADA’s market value reached $30 billion, underscoring its indispensability in industrial automation. Its expected growth of 7.5% annually till 2026 highlights its critical role in industrial advancement.

The Transition from Wired to Wireless Systems

The shift to wireless SCADA systems introduces a new era of adaptability and cost savings. Despite the robustness of traditional systems, they were complex and limited by physical constraints. This shift overcomes those barriers and improves interoperability with IoT technologies and an existing SCADA network. It enables efficient real-time data gathering from widespread assets.

Advantages of Wireless Systems in Remote Monitoring

Wireless SCADA offers significant benefits in remote monitoring, like reduced downtime and lower maintenance costs. The integration of wireless technologies enables the efficient transfer of live and historical data to centralized locations. This advantage bolsters network monitoring, threat detection, and real-time analytics. Consequently, it improves decision-making and operational agility. Furthermore, it enhances security through advanced encryption, addressing the growing concern of IoT security challenges faced by 99% of security professionals.

The integration of SCADA with IoT technologies opens up vast opportunities for operational efficiency and detailed data analysis. The transition to wireless is not just a current trend but a crucial development in industrial automation’s ongoing narrative. It ushers in more flexible, secure, and efficient operations.

Fundamentals of SCADA: Components & Operations

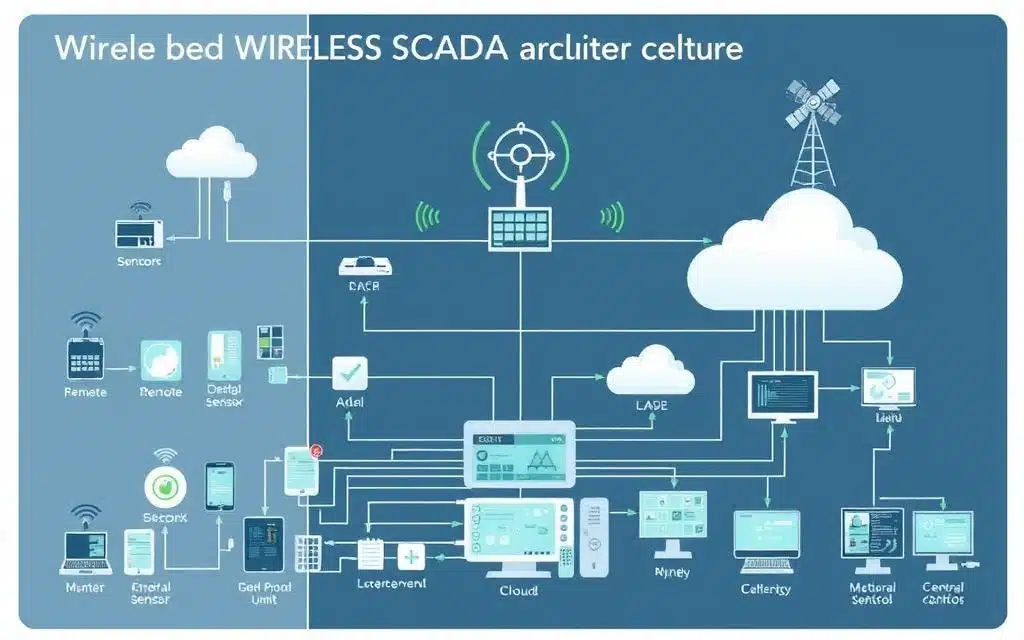

At the heart of every robust industrial automation system is its architecture, especially the wireless SCADA system architecture. It’s crucial to understand its main components and functions to fully utilize the system’s capabilities.

First, we must examine the essential components: Field Instruments, a Programmable Logic Controller (PLC) or Remote Terminal Unit (RTU), Communications Link, and a Central Computer Station. Each plays a crucial role in smooth operations. The PLC, brought to life by Dick Morley in 1968, and its equivalents—RTU and PAC—act as the core processing units. They process data from devices that measure real-world conditions.

Communications span various platforms through SCADA communication protocols like ModBus, DNP3, and ControlNet. These protocols ensure secure and efficient data transmission between field and central locations. They are essential for moving telemetry data over complex networks. SCADA’s scalability allows it to manage systems ranging from a few to several thousand points. This flexibility is a hallmark of its solid wireless SCADA system architecture.

The HMI (Human Machine Interface) is integral to SCADA discussions. HMIs offer an intuitive platform for overseeing SCADA operations. They facilitate tasks like real-time data viewing, process parameter adjustments, and system troubleshooting.

SCADA’s application in fields like electric utilities, water management, and transport underscores its adaptability. In electric utilities, it controls power flow and circuit breakers effectively. Water management uses it to regulate water levels and pumps efficiently. Transit authorities rely on SCADA to manage traffic signals and power supplies, ensuring smooth transport operations.

In summary, the wireless SCADA system architecture not only accommodates complex and vast industrial settings, but it also boosts operational reliability and efficiency. This is done through advanced SCADA communication protocols and user-friendly HMIs.

Wireless SCADA System Architecture

The architecture of wireless SCADA systems is crucial in today’s industrial settings. It brings enhanced communication and control. This discussion highlights the main elements of this architecture, focusing on wireless sensor networks, the integration of SCADA with IoT, and the Human-Machine Interface (HMI).

Examining the Structure of SCADA Networks

Wireless SCADA networks primarily enable remote process control and monitoring. They support real-time data collection, facilitating direct interactions with devices over private radio networks. Additionally, they log data and events. Evolving from analog systems of the 1960s, these networks have become sophisticated digital solutions for industrial operations.

Role of Wireless Sensor Networks in SCADA

Wireless sensor networks play a key role in SCADA architecture. They monitor data points like environmental conditions and equipment metrics, including temperature and pressure. Providing this data to SCADA systems is crucial for automation and improving operational visibility in sectors such as agriculture, mining, and utilities.

Integration of HMI & IIoT in Wireless SCADA Systems

The integration of HMI in wireless SCADA systems offers a user-friendly graphical interface. It simplifies operation visualizations and makes it easier for operators to interact with the system. These solutions enable remote and localized control of data transfer and monitoring processes. The addition of IIoT technologies to SCADA systems enhances their capabilities, allowing real-time communication and data analysis. This is vital for industries aiming to minimize downtime and boost efficiency.

The architecture of wireless SCADA systems forms a strong foundation for reliable, efficient industrial operations. By integrating advanced technologies like wireless sensor networks, SCADA integration with IoT technologies, and HMI, these systems lead in automation and control solutions.

Core Technologies Behind Wireless SCADA Systems

Modern industrial setups heavily rely on Wireless SCADA systems for crucial data management and control. At their core, SCADA communication protocols play a pivotal role. These protocols are crafted to enable secure and efficient data sharing. This is vital for comprehensive management of industrial processes.

Overview of SCADA Communication Protocols

SCADA systems stand on the foundation of advanced communication protocols. These ensure a smooth data flow from the operational floor to the control room. Protocols like DNP3 and IEC 60870 are widely used for their durability and data integrity capabilities in varied industrial settings. They navigate the massive data flows from field devices to central monitors, granting operators instant access to essential operational insights.

The Impact of DNP3 & IEC 60870 Protocols in SCADA

Protocols DNP3 and IEC 60870 don’t just allow for efficient data collection; they also boost SCADA systems’ security. They introduce many layers of fail-safes and encryption, key in blocking unauthorized access and preserving data integrity during transmission. Grasping these protocols’ complexities is key to upholding SCADA systems’ effectiveness and security.

Advantech Digital’s Contribution to Wireless Infrastructure

Advantech Digital excels in industrial solutions, offering innovative components compatible with SCADA systems using DNP3 and IEC 60870. Their technology strengthens the infrastructure of numerous industrial applications, ensuring both reliability and effectiveness. Discover the workings of SCADA with these advancements at Advantech’s comprehensive guide.

With Advantech Digital entering the SCADA communication scene, the standards for connectivity and resilience are redefined. Their emphasis on integrating advanced protocols like DNP3 and IEC 60870 keeps SCADA systems not just operational but also secure against evolving security threats.

Wireless SCADA System

In the realm of industrial automation, wireless SCADA systems represent a crucial advancement. They enable real-time data acquisition and control. This leap over traditional wired systems offers clear benefits. Notably, the absence of physical cables lowers the risk of disruptions, boosting reliability in industrial operations.

Wireless technology in wireless SCADA systems supports communication over broad, challenging terrains and remote locations. This is vital in industries such as oil and gas, and utilities. The ability to monitor and control these areas remotely is not just convenient. It’s essential for maintaining safety and efficiency.

Key benefits of wireless SCADA systems in industrial automation include:

Reduced installation and operational costs due to the absence of extensive cabling

Enhanced flexibility and system expansion ease with Point-to-Multipoint (PTMP) configurations

Better data transmission rates and security via Point-to-Point (PTP) configurations

Strong encryption protocols like WPA3 safeguard against data breaches

Effective employment of long-distance communication technologies, such as VHF and UHF radio frequencies

Raveon’s technology integration showcases the practical benefits of wireless SCADA systems. Products like the RV-M21 RTU and the M7 series of data modems provide customized solutions. These enhance SCADA networks’ scalability and performance.

In an era focused on efficiency and cost-effectiveness, wireless SCADA systems herald a new strategy in industrial automation. They not only support real-time data acquisition but also offer flexibility to adapt to future needs. This makes them superior to their wired counterparts.

By adopting wireless SCADA technology, industries can navigate geographical and logistical hurdles. This marks a step towards more robust, flexible infrastructure. For sectors requiring extensive, precise control over remote operations, this technology is invaluable.

Implementing Robust Wireless SCADA Security Measures

In the realm of industrial automation, securing wireless SCADA systems demands careful thought and systematic strategy. Diving into cybersecurity for these systems uncovers the necessity for a layered defensive approach. This isn’t just a recommendation—it’s crucial.

Challenges in SCADA Security

SCADA networks power critical services but prioritize functionality over security. This focus leaves them open to interruptions and hostile actions. Addressing the security vulnerabilities of SCADA networks is thus essential, needing immediate and thorough action.

Best Practices for Securing Wireless SCADA Networks

To shield wireless SCADA networks from threats, experts suggest several key practices. These include minimizing non-essential connections, reinforcing current links, conducting regular checks, and installing advanced detection systems. Additionally, evaluating physical security to prevent unauthorized access is vital.

Efforts recommended by the President’s Critical Infrastructure Protection Board, alongside the Department of Energy, highlight 21 protective steps for SCADA security. These measures aim to diminish risks and bolster the durability of these crucial setups.

Cybersecurity & the Role of Encryption in SCADA

Encryption is fundamental in SCADA’s cybersecurity framework. It turns sensitive data unreadable to those without permission, keeping it secure. This protection is key for the safety and privacy of industrial information, averting potential severe outcomes.

The widespread use of SCADA systems in sectors like power, water, and transportation underscores the importance of their security. Boosting their security not only benefits but is vital for their uninterrupted, trustworthy operation.

Taking a thorough stance on SCADA security, through detailed evaluations, firm cybersecurity practices including mandatory encryption, and alert management, is essential. It guarantees that our indispensable infrastructures withstand the test of evolving dangers.

Real-Time Data Acquisition & Management in Wireless SCADA

In today’s fast-changing industrial landscape, real-time data acquisition and management via wireless SCADA systems are crucial. These systems ensure smooth and secure operations through continuous monitoring and control.

The essence of wireless SCADA systems lies in their swift data gathering from dispersed sensors and units. It’s not just about data collection but interpreting it instantly for timely decision-making and efficiency.

SCADA technologies, including cellular and satellite communications, cut down on delay and uphold data integrity. This means anomalies are quickly communicated to operators. Quick actions can then be taken to address potential issues.

Wireless SCADA systems, with advanced diagnostics, boost preventive maintenance, reducing downtime and prolonging equipment life.

Data not only supports real-time adjustments but is central to strategic planning. Linking wireless SCADA with enterprise systems enables thorough analysis. This helps optimize workflows and enhance productivity at every operation level.

Immediate notification and response to system alerts

Enhanced operational visibility

Improved safety and compliance monitoring

Efficient resource management and reduced waste

In summary, adopting wireless SCADA systems is a key advance in industrial operation management. With real-time data as a pivotal aspect, these systems facilitate managing complex environments more effectively and sustainably.

Optimizing Operations: Tailoring SCADA Systems for Efficiency

To unlock the full potential of SCADA system optimization, understanding its wide range of applications is crucial. Industries such as oil and gas, manufacturing, and renewable energy can significantly improve their operations and boost industrial automation efficiency by utilizing integrated control systems.

In the oil and gas sector, SCADA systems are key for overseeing vast pipeline networks and refining operations. Optimizations in water and wastewater management are also essential, focusing on treatment and distribution to ensure efficiency and safety.

In manufacturing, combining SCADA with automated machinery and assembly lines streamlines processes and minimizes downtime. This improvement is vital for staying competitive in the fast-paced industrial world.

Renewable energy fields, like wind farms and solar power plants, rely on SCADA optimization to adapt to environmental shifts and manage energy production efficiently. This enhances the overall industrial automation efficiency significantly.

SCADA optimization is more than mere automation; it fosters a responsive and flexible infrastructure. It allows industries to manage resources more efficiently, anticipate maintenance, and improve safety measures. These advancements are key to sustainability and reliability.

Industries focusing on smart configurations and efficient data use are not just optimizing current operations. They are also preparing for future progress in industrial automation efficiency. The shift towards more integrated and intelligent systems, as this SCADA systems study suggests, leads to smarter industry practices. These practices aim for greater efficiency and reduce operational costs.

Hence, for industries aiming to boost scalability and flexibility, adopting SCADA system optimization is essential. The advantages include improved efficiency, lower downtime, and a resilient system ready for future challenges.

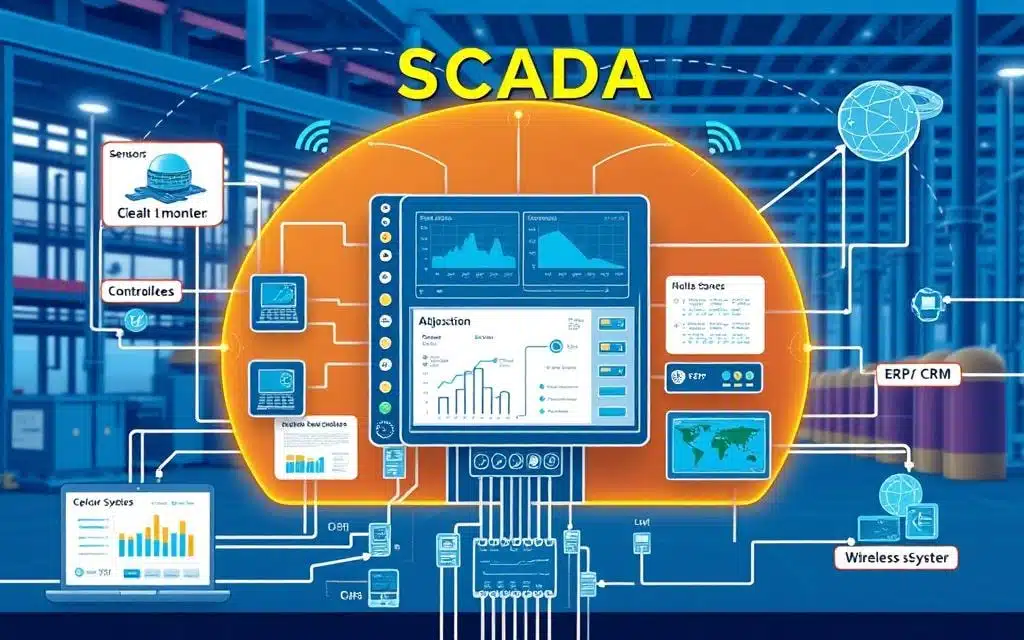

Integrating SCADA with Other Enterprise Systems

In the industrial management domain, integrating SCADA systems with wider enterprise structures, like ERP systems and IoT technologies, marks a strategic move for deeper insights and improved operational efficiency. We delve into the seamless blend of these technologies, highlighting the great prospects and the complex challenges.

SCADA and ERP Systems: A Harmonious Connection

The bond between SCADA and ERP systems creates a dynamic foundation for operational control and business strategy. It fosters real-time decision-making, boosting adaptability to changes in production or energy use. For example, merging SCADA with ERP reveals a detailed asset performance view, aiding maintenance plans and investment choices.

The Future of SCADA Integration with IoT & Big Data Analytics

The merge of SCADA with IoT technologies and Big Data Analytics ushers in smarter industrial activities. SCADA software facilitates communication between operators and various system components, such as PLCs and RTUs, through user-friendly interfaces. IoT devices feed continuous data for SCADA systems to monitor and study. This key integration propels predictive maintenance, energy optimization, and system durability. Through Big Data analytics, firms can spot trends and forecasts missed by old methods, leading to smarter decisions and creative solutions.

Challenges of Integration & How to Overcome Them

While the advantages are clear, fusing SCADA with other enterprise solutions invites compatibility, cybersecurity, and data handling hurdles. Achieving seamless data interoperability, especially with dated technologies, demands careful system design and middleware use. Additionally, as connections increase, so do potential security risks. Firms need to enforce strict cybersecurity protocols, including VPNs, and maintain system updates and patches.

To understand the evolution and integration of SCADA systems across sectors in recent years, consider these insights:

Year | Innovation/Integration | Impact |

|---|---|---|

2004-2005 | Enforcement of NERC Standard 1200 | Higher focus on cybersecurity in SCADA systems |

Past Decade | IoT and Big Data integration in SCADA | Better predictive maintenance and operational efficiency |

Ongoing | Transition to up-to-date platforms | Lower downtime and maintenance costs |

As the journey continues, SCADA’s importance in industrial automation and data analysis will grow. Overcoming integration challenges and boosting the connection between SCADA, IoT, and ERP will be key for any business aiming to thrive in the fast-changing digital environment.

Case Studies: Successful Deployments of Wireless SCADA Systems

In our comprehensive analysis, we’ve seen wireless SCADA systems revolutionize sectors like water treatment, oil and gas, and power generation. Through Advantech Digital’s efforts, these projects leverage cutting-edge wireless innovations. They enhance operational efficiencies while ensuring stringent security protocols.

Industrial Success Stories with Wireless SCADA

Wireless SCADA has become key to boosting efficiency in critical infrastructure, slashing wiring costs, and bolstering real-time monitoring. A standout instance involved deploying advanced wireless networks. This enabled decentralized sites to work together seamlessly. It guaranteed secure, dependable data exchange crucial in managing essential resources.

Examining the Role of Advantech Digital in SCADA Implementations

Advantech Digital has been instrumental in SCADA advancements, introducing ground-breaking tech for more cohesive HMI and IIoT integration. Their deep expertise led to success in various industrial domains. This highlights the need for custom solutions that meet the specific demands of intricate infrastructures.

Lessons Learned from Wireless SCADA System Upgrades

Recent updates emphasize the vital role of innovation and training in keeping wireless SCADA systems efficient. With the adoption of more complex networks, like Motorola RTUs at water sites, security has become more critical. Addressing potential cyber risks, understanding vulnerabilities, and applying advanced encryption are now core to safeguarding SCADA systems.

The upgrade to advanced SCADA communication protocols, like TCP/IP versions of DNP3 and Modbus, marks a significant step forward. It ensures messages move reliably across elaborate networks. This adaptation supports vital data flows and sustains system integrity and reliability in all collaborations with Advantech Digital.

Conclusion

Our journey into the world of wireless SCADA systems has highlighted their essential role in advancing industrial automation. These systems have evolved from using traditional line communication within private networks. They have seamlessly embraced wireless technology, marking a substantial advance in functionality. This shift is pivotal, as industrial process control now relies on both sophisticated hardware like PLCs and RTUs and cutting-edge communication protocols.

The adoption of open software systems enhances interoperability across diverse hardware platforms. This integration is crucial for modernizing operations.

The transition to wireless technology has markedly improved SCADA security by addressing the need for specialized personnel and meticulous planning. This change addresses cybersecurity concerns effectively. It has made remote monitoring possible, thereby increasing safety and operational efficiency. This efficiency is achieved through reduced manual intervention in crucial industrial processes. By merging PLCs, RTUs, and digital communication, wireless SCADA systems offer a comprehensive view of industrial operations.

This allows for more informed and timely decision-making. Companies like Advantech Digital are at the forefront of this innovation, signaling a readiness for future technological breakthroughs.

Looking ahead, the evolution of industrial automation is shaped by current progress and successes. The integration of IoT, big data analytics, and enterprise systems reflects the adaptable, future-oriented nature of wireless SCADA systems. As we embrace this technology, it is our duty to ensure that we maintain a focus on enhancing safety, efficiency, and quality in our operations.

FAQ

What is a wireless SCADA system?

A wireless SCADA system incorporates both software and hardware to monitor and control industrial operations from afar. Through wireless communications, it collects real-time data. This facilitates industrial automation remotely.

How have SCADA systems evolved with wireless technology?

With wireless advancements, SCADA systems have transitioned from wired, manual operations to automated, remote monitoring. This shift leverages the latest in wireless technologies and infrastructure and integrates IoT, boosting efficiency and flexibility.

What are the benefits of using a wireless SCADA system?

Wireless SCADA systems bring down installation costs and offer scalability. They provide deep insights through improved data analysis. Immediate operational reactions are possible, making supervision in remote or tough settings feasible. The addition of HMI and IIoT furthers control and response times.

What components are essential for SCADA system architecture?

Key SCADA architecture elements include supervisory systems and PLCs. Required too are HMIs, RTUs, and secure communication protocols such as DNP3 and IEC 60870. These ensure data is transferred reliably and securely.

How do wireless sensor networks enhance SCADA systems?

Wireless sensor networks boost SCADA systems by ensuring efficient communication. They link control centers with distant sensors or devices. Especially over large areas, they’re key for real-time monitoring and control.

What is the role of Advantech Digital in wireless SCADA?

Advantech Digital enhances SCADA’s wireless foundations with its technological solutions. Its efforts secure networks from cyber threats. Such innovation is crucial for industrial automation’s future.

Why is security a major consideration in wireless SCADA systems?

Security is critical in wireless SCADA because these systems oversee vital infrastructure. To protect against cyber threats and unauthorized access, implementing strong encryption and security protocols, like IPSec tunnels, is crucial for protecting sensitive data.

How does real-time data acquisition impact industrial automation?

Real-time data acquisition is essential for efficiently overseeing industrial operations. It collects, analyzes, and acts on data instantly, allowing for a swift reaction to any issues. This reduces downtime and boosts productivity.

What strategies are used to optimize SCADA systems for better efficiency?

Enhancing SCADA efficiency involves network design attention and proper component integration. Using standardized protocols and interoperability tech is key. Protocol translation and configuration streamline operations further.

How does integrating SCADA with IoT and enterprise systems benefit industries?

SCADA’s integration with IoT and enterprise systems, like ERP, leads to smarter industrial management. It offers advanced decision-making, deeper data insights, and predictive maintenance capabilities. Such integration fosters efficient, proactive operations.

Can you provide examples of successful wireless SCADA system deployments?

Certainly, there are many success stories of wireless SCADA use. Advantech Digital, for instance, has boosted operational excellence across industries. It achieved this through enhanced wireless SCADA systems and seamless system integration.